Welcome to Jiangsu Rongyi

QIRUN

DURALE STEEL

MANUFACTURER SUPPLY

Qirun Steel Advanced

Powerful backing

- Ideal placement close to major transport routes enhances logistics and distribution efficiency.

- Nearby related industries facilitate partnerships and collaborative development efforts.

- State-of-the-art infrastructure and large buildings support various production and operational activities.

- Reliable utilities ensure uninterrupted manufacturing processes and operational consistency.

- Extensive equipment and multiple production lines maximize efficiency and product variety.

- Robust environmental measures and greenery reduce ecological impact and improve workplace quality.

- Investment in R&D and skilled personnel fosters innovation and industry leadership.

- Comprehensive safety protocols protect workers and maintain equipment integrity.

Why choose us?

Choosing us means choosing a solid backing!

Company Introduction

Jiangsu Rongyi Metal Co., Ltd. boasts over 20 years of experience in the steel industry. Annual sales approach 1 billion RMB, with a steel output of approximately 300,000 tons.

Located in Wuxi City, the company has established strategic partnerships with major domestic steel enterprises such as Rizhao Steel, Jinan Steel, Laiwu Steel, Handan Steel, Ansteel, and Maanshan Steel. Jiangsu Rongyi Metal Co., Ltd. is the largest steel distributor in Shandong Province. The company owns its own steel production plant, with an annual inventory of no less than 10,000 tons.

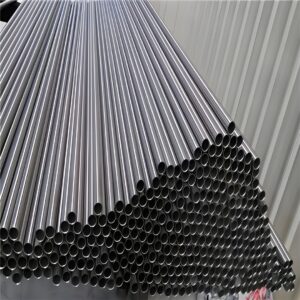

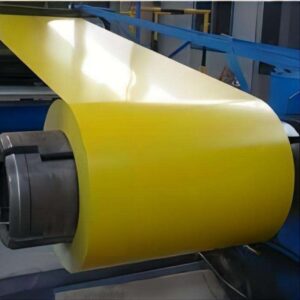

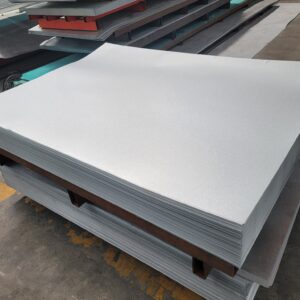

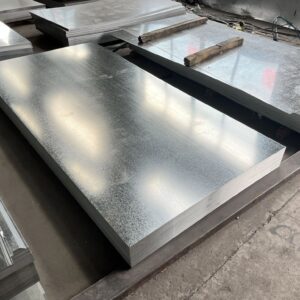

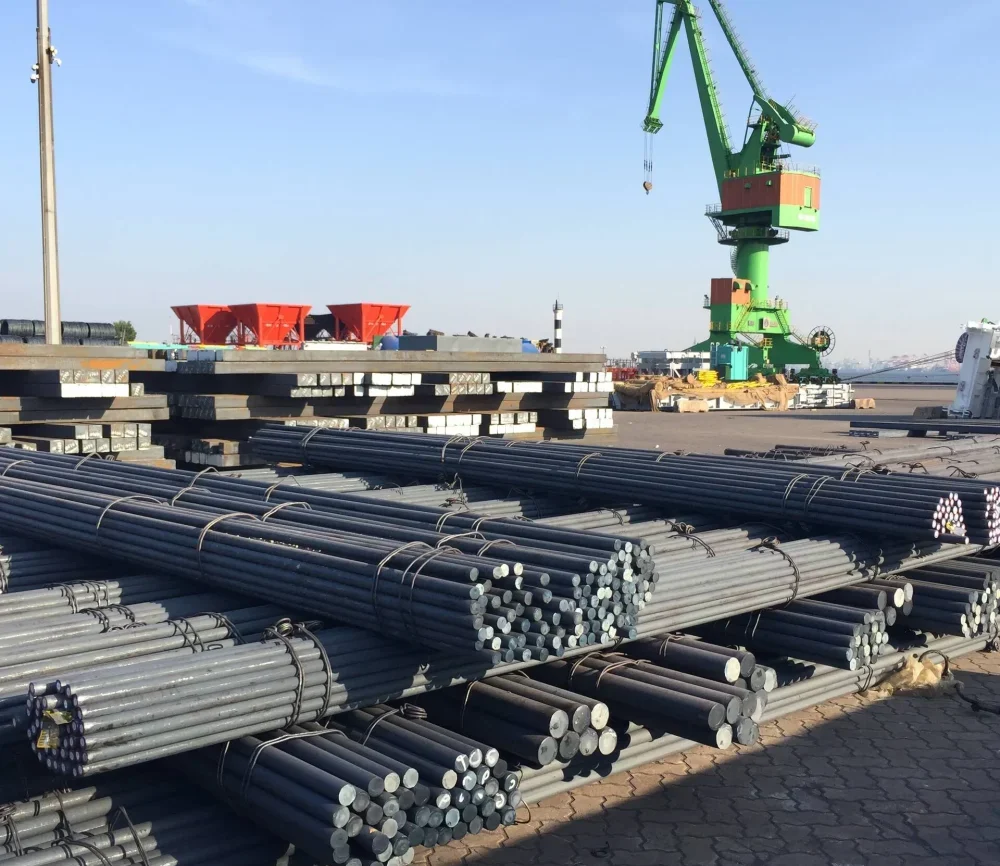

The company's main business includes: color-coated coils, galvanized steel sheets, roofing panels, H-beams, AFP aluminum-zinc coated steel sheets, stainless steel, steel pipes, I-beams, angle steel, channel steel, flat steel, round steel, and various profiles. We own our own steel mill, primarily producing square tubes, seamless pipes, spiral pipes, galvanized pipes, and other steel products.

We consistently emphasize resource integration and adhere to the principle of win-win cooperation. Thanks to the concerted efforts of all our employees, we have served clients from over 20 countries and regions, earning widespread praise and ultimately becoming their close friends and partners. We welcome friends from all walks of life to visit, provide guidance, and discuss business opportunities.

Hot products

Stainless steel pipe

Read more

Stainless steel pipe

Read more

Stainless steel wire

Read more

Stainless steel elbow pipe

Read more

Stainless steel round bar

Read more

Colored coated roll

Read more

Colored coated tiles

Read more

Colored coated tiles

Read more

Aluminum-coated zinc sheet

Read more

Aluminum-coated zinc sheet

Read more

Galvanized steel sheet

Read more

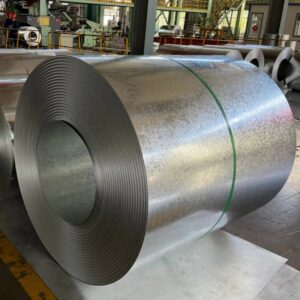

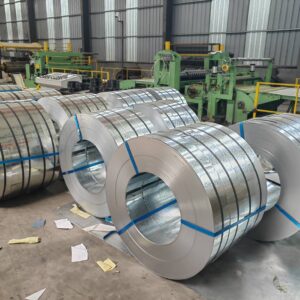

Galvanized steel coil

Read more

Galvanized steel coil

Read more

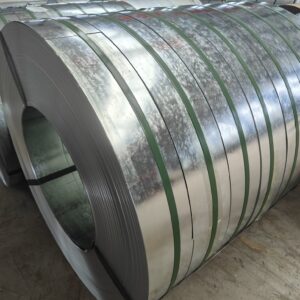

Galvanized steel strip

Read more

Galvanized steel strip

Read more

Galvanized square pipe

Read more

Powerful supply chain

A strong supply chain guarantees the stability of product delivery

Establish long-term and stable cooperative relationships with high-quality suppliers of raw materials such as iron ore and coal to ensure the availability and quality of raw materials, free from market fluctuations and supply shortages.

It has a perfect logistics network, including the coordinated operation of various transportation methods such as railways, highways, and waterways, which can transport raw materials in and finished products out in a timely, safe, and low-cost manner.

Adopt modern production processes and high-end equipment to improve production efficiency and product quality, while being able to adjust production plans flexibly to adapt to changes in market demand.

In all aspects of the entire supply chain, from raw material procurement to finished product delivery, rigorous quality inspection and monitoring are implemented to ensure that products meet high standards and specific customer requirements.

Through precise demand forecasting and inventory optimization strategies, it is possible to both meet the urgent order demands of customers and avoid the cost increase and capital occupation caused by excessive inventory.

Utilize advanced information technology to achieve real-time data sharing and collaborative work in all aspects of the supply chain, improve the accuracy and response speed of decision-making, and effectively respond to various emergencies.

After Sale Service

We Provide

Service processes and mechanisms

1. Quick response: Customer inquiries or feedback can be responded to immediately, and various channels such as telephone, online customer service, and email are kept open to ensure that customers can contact after-sales services at any time.

2. Clear process: There is a clear, standardized and transparent service process, with clear responsibilities for each link and clear time nodes. The whole process can be traced from the customer’s question to the final solution.

3. Proactive follow-up: After the problem is solved, take the initiative to return to the customer to understand satisfaction, collect opinions, and continuously improve the service.

We Provide

Service team and support

1. Professional team: After-sales personnel have rich professional knowledge and experience, enabling them to accurately diagnose and solve problems.

2. Sufficient spare parts: Establish a complete spare parts supply system to ensure the timely supply of spare parts and reduce maintenance waiting time.

3. Training and knowledge sharing: Conduct regular after-sales personnel training, update knowledge and skills, and establish an internal knowledge base for easy inquiry.

4. Data analytics: Through the analysis of service data, identify problem trends and provide a basis for product optimization and service improvement.

5. Customer satisfaction assessment: Build a scientific evaluation system to measure service quality and motivate employees to improve service levels.

Hign efficient Product & Strictly inspection

Ensuring Peak Efficiency in Steel Production through Rigorous Quality Inspections: A Commitment to Precision, Performance, and Excellence in Every Stage of the Manufacturing Process, Guaranteeing Superior Strength and Reliability in Every Steel Product Delivered.

Steel plate

Advanced Steel Plate Production and Quality Assurance

Steel coil

High-Quality Steel Coil Production and Inspection Services

Steel pipe

Steel Pipe Manufacturing Excellence and Rigorous Testing

Steel Product Shipping Logistic

With a steadfast commitment to excellence, we ensure timely and professional delivery of steel products through our maritime logistics. Our dedication to maintaining high standards and honoring agreements reflects our unwavering resolve to meet and exceed client expectations every time.