PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

304 stainless steel coil

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details table:

| Item | Details |

|---|---|

| Product Name | 304 stainless steel coil |

| Material Type | Austenitic stainless steel. Main components: approximately 18% Chromium (Cr), about 8% Nickel (Ni), Carbon (C) ≤ 0.08%. The rest consists of Iron (Fe) along with trace amounts of Manganese (Mn), Silicon (Si), Phosphorus (P), and Sulfur (S). |

| Execution Standard | GB/T 3280 |

| Specifications | – Thickness: 0.1mm – 6.0mm – Width: 600mm – 1500mm – Inner diameter: 508mm (standard) – Outer diameter: Determined by coil weight, usually ≤ 2500mm – Weight: Standard coil weight 3 – 10 tons, customizable. |

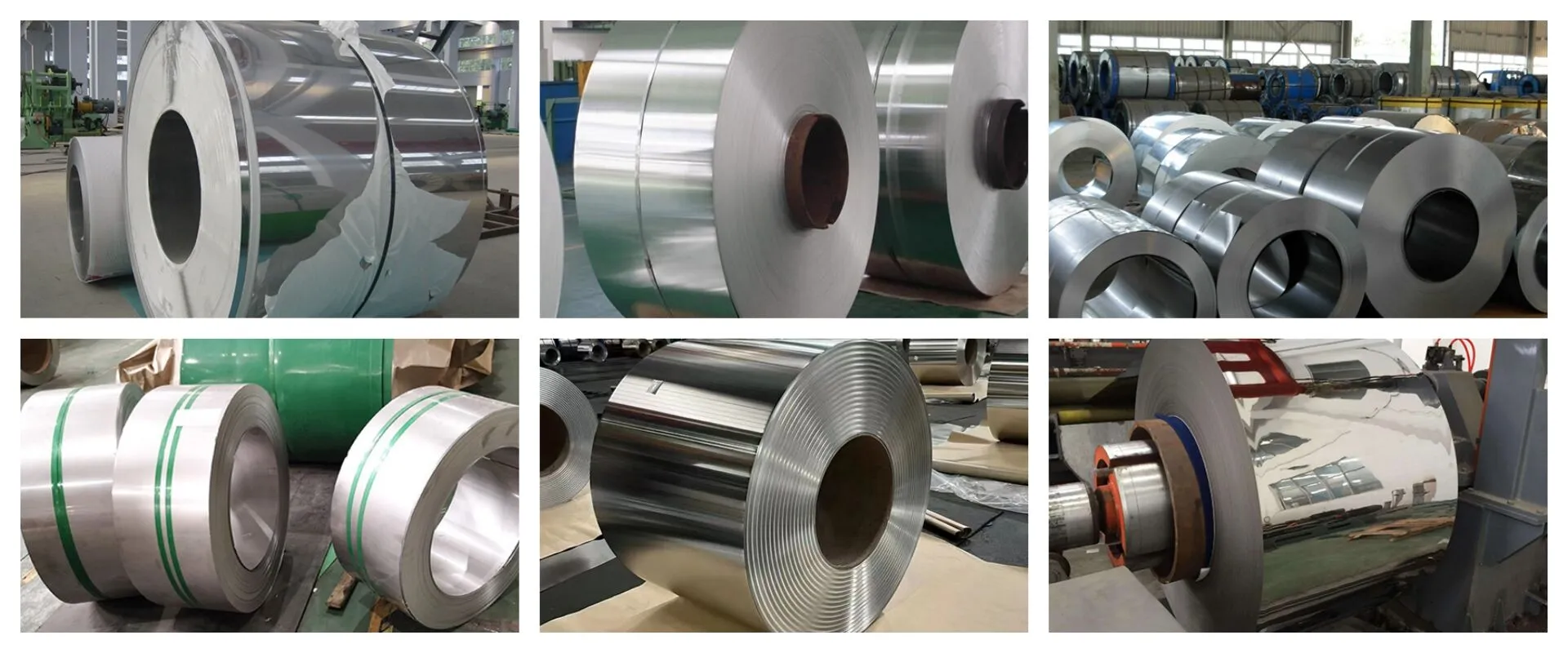

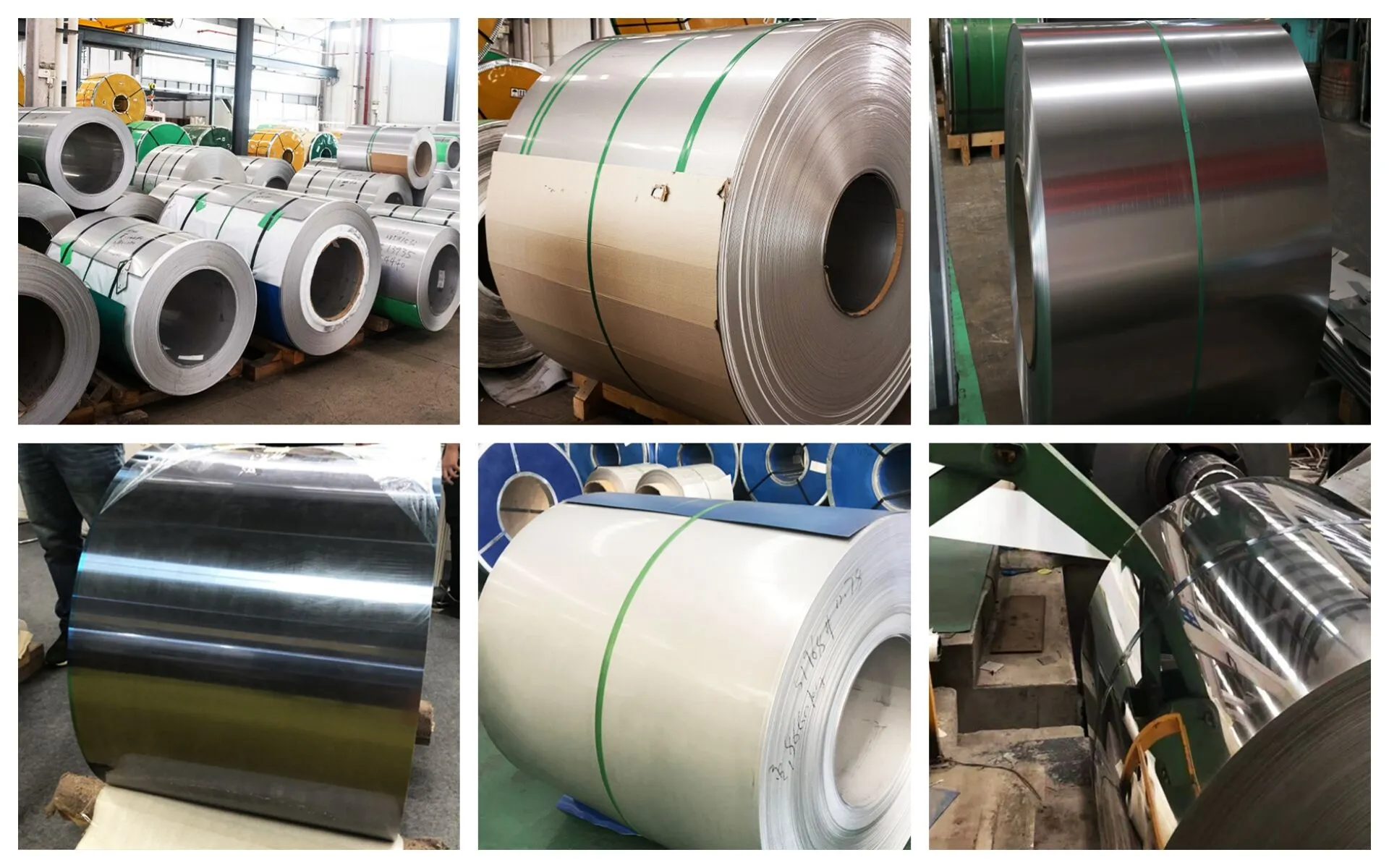

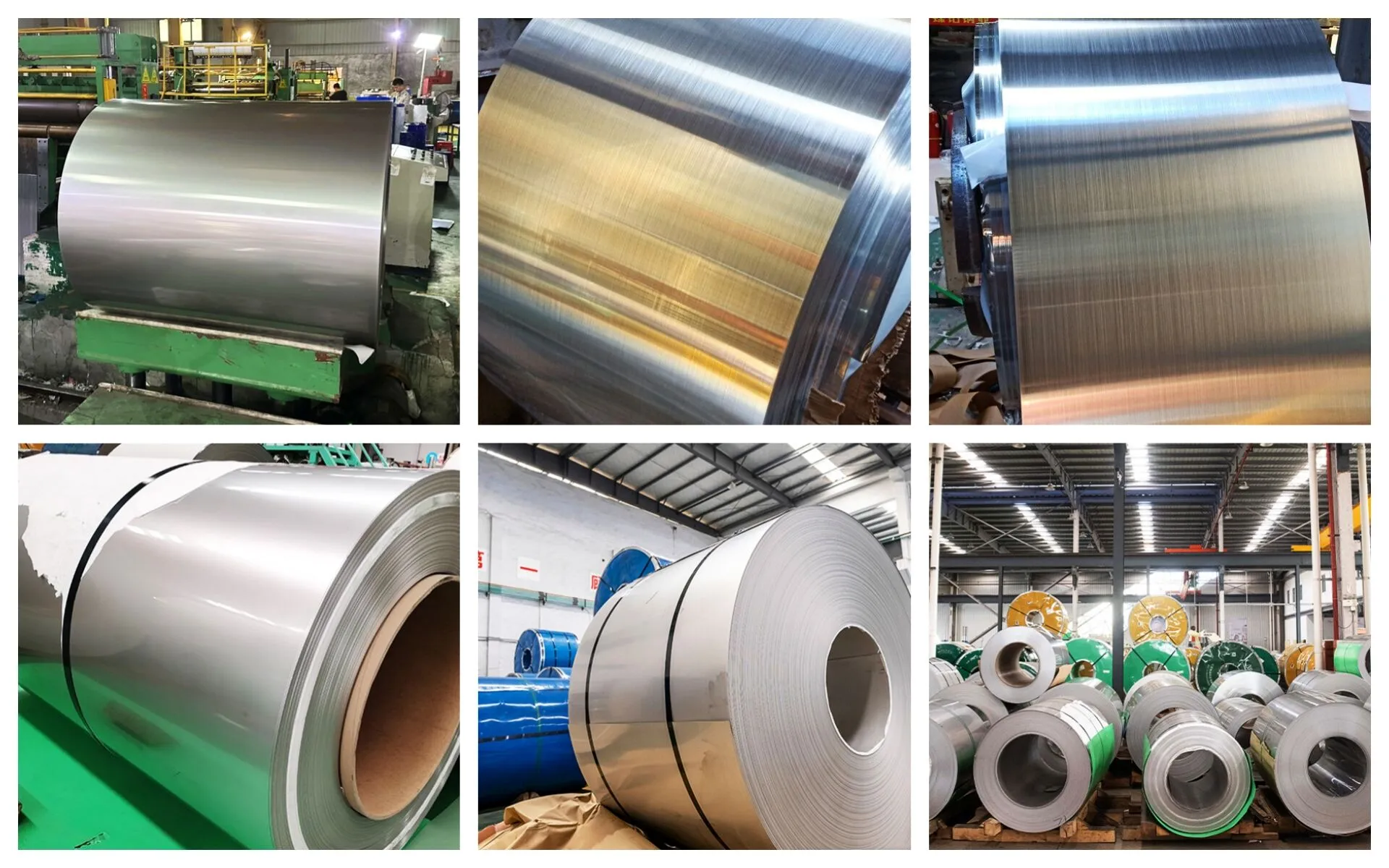

| Surface Treatment | 2B (cold-rolled bright), BA (bright annealed), No.4 (satin finish), HL (hairline finish), mirror polish; passivation treatment, oil coating for rust prevention. |

| Mechanical Properties | – Tensile strength: ≥ 520MPa – Yield strength: ≥ 205MPa – Elongation: ≥ 40% – Hardness: HB ≤ 187, HRB ≤ 90, HV ≤ 200 – Density: 7.93g/cm³ |

| Physical Characteristics | Non-magnetic (may develop weak magnetism after cold working). Operating temperature range: -196°C – 800°C. Coefficient of thermal expansion: 17.3×10⁻⁶/°C (20 – 100°C). Thermal conductivity: 16.2W/(m・K). Electrical conductivity: 1.4×10⁶ S/m. |

| Corrosion Resistance | Chromium forms a dense oxide film, providing resistance to the atmosphere, water, and weak acids and alkalis. It performs well in oxidizing acids (such as boiling nitric acid with a concentration ≤ 65%), alkali solutions, and most organic acids. However, it has lower resistance to environments with chloride ions (compared to 316 stainless steel). |

| Typical Applications | – Architectural decoration: curtain wall panels, ceilings, elevator panels – Home appliance manufacturing: refrigerator panels, washing machine inner drums, air conditioner casings – Food equipment: storage tanks, conveyor belts – Chemical industry: reactor linings, pipes – Automobile manufacturing: exhaust systems, vehicle body structural components |

| Processing Technology | Cold rolling (high precision, thin specifications), hot rolling (thick specifications, low cost), slitting (customizable width), cutting to flat sheets, forming processing (stamping, bending) |

| Packaging Method | Wrapped with moisture-proof paper and plastic film, with steel corner protectors for edge protection; horizontally or vertically packaged, suitable for sea and land transportation. |

| Delivery Period | Regular specifications: 3 – 7 working days; Customized specifications: 7 – 15 working days |

| Quality Certifications | ISO 9001 quality management system certification, SGS inspection report, RoHS environmental certification |

Physical properties and chemical properties:

Physical properties

Appearance:

Usually silver-gray, with a smooth surface and metallic luster.

Density:

About 7.93g/cm³, which is moderate compared to other common metals.

Magnetism:

Non-magnetic, but may produce weak magnetism after cold processing.

Melting point:

The melting point is between 1398-1454℃, with a high melting point, and can maintain good stability in high temperature environments.

Coefficient of thermal expansion:

In the temperature range of 20-100℃, the coefficient of thermal expansion is about 17.3×10⁻⁶/℃. As the temperature changes, its size will expand or shrink to a certain extent.

Thermal conductivity:

The thermal conductivity is 16.2W/(m・K), with good thermal conductivity and the ability to quickly transfer heat.

Electrical conductivity:

The electrical conductivity is about 1.4×10⁶ S/m, which has a certain degree of electrical conductivity.

Chemical properties

Chemical properties

Corrosion resistance:

304 stainless steel coils contain alloy elements such as chromium (Cr) and nickel (Ni). Chromium easily reacts with oxygen in the air and forms a dense chromium oxide film on the surface. This oxide film can prevent the internal metal from further chemically reacting with external substances, making it have good corrosion resistance and can resist corrosion from weak corrosive media such as atmosphere, water, and steam, as well as chemically corrosive media such as acids, alkalis, and salts.

Oxidation resistance:

At room temperature, 304 stainless steel coils have good oxidation resistance. In high temperature environments, its oxidation resistance is also better than that of ordinary carbon steel, but oxidation reactions may still occur under specific high temperatures and strong oxidizing atmospheres.

Stability:

In general chemical environments, 304 stainless steel coils have high chemical stability and are not prone to chemical reactions that change their properties. However, in some special cases, such as long-term exposure to chloride ion environments, pitting or stress corrosion cracking may occur.

Application:

Application:

304 stainless steel coil is made of austenitic stainless steel with 18% chromium, 8% nickel and other alloy elements. It forms a dense passivation film on the surface and has excellent corrosion resistance and oxidation resistance. It has high strength and good toughness. It can be cold/hot rolled and has a variety of surface treatments such as 2B and BA. It is widely used in architectural decoration, home appliance manufacturing, food and medical fields. It is a metal coil that combines practicality and aesthetics.