PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Stainless steel pipe

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product Details Table:

| Items | Details |

|---|---|

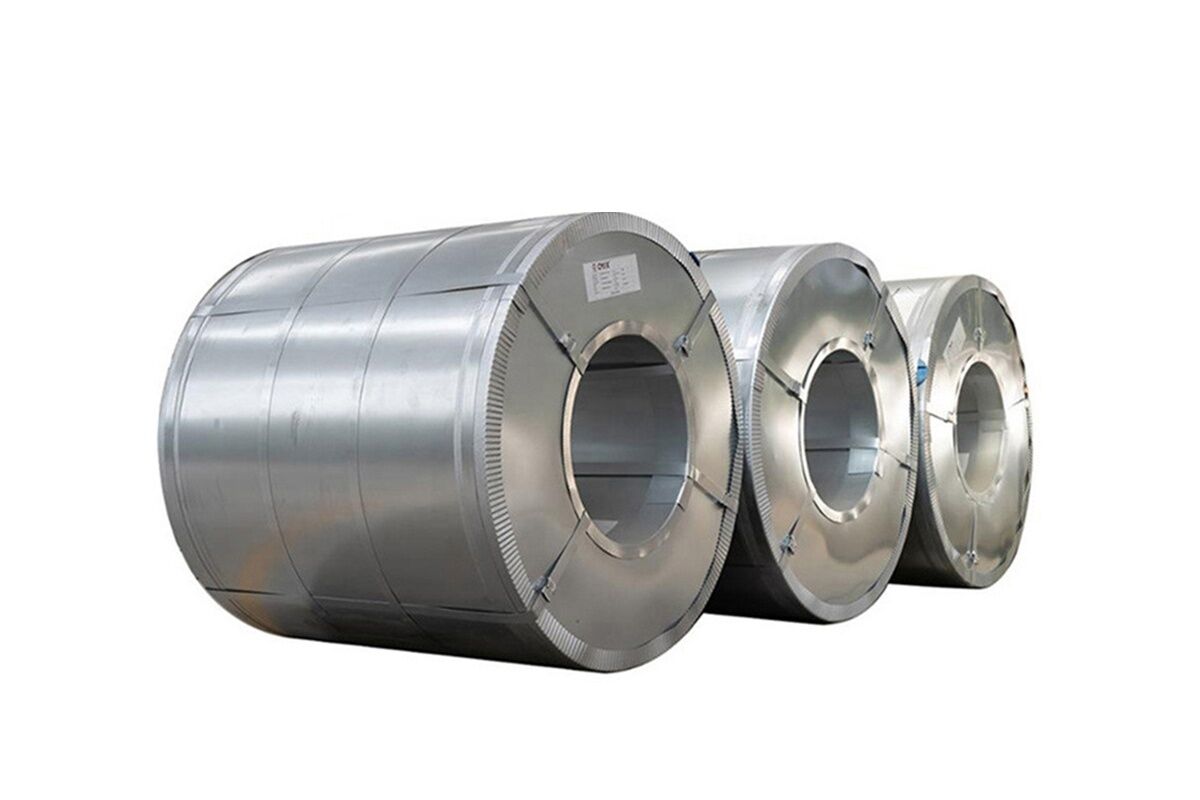

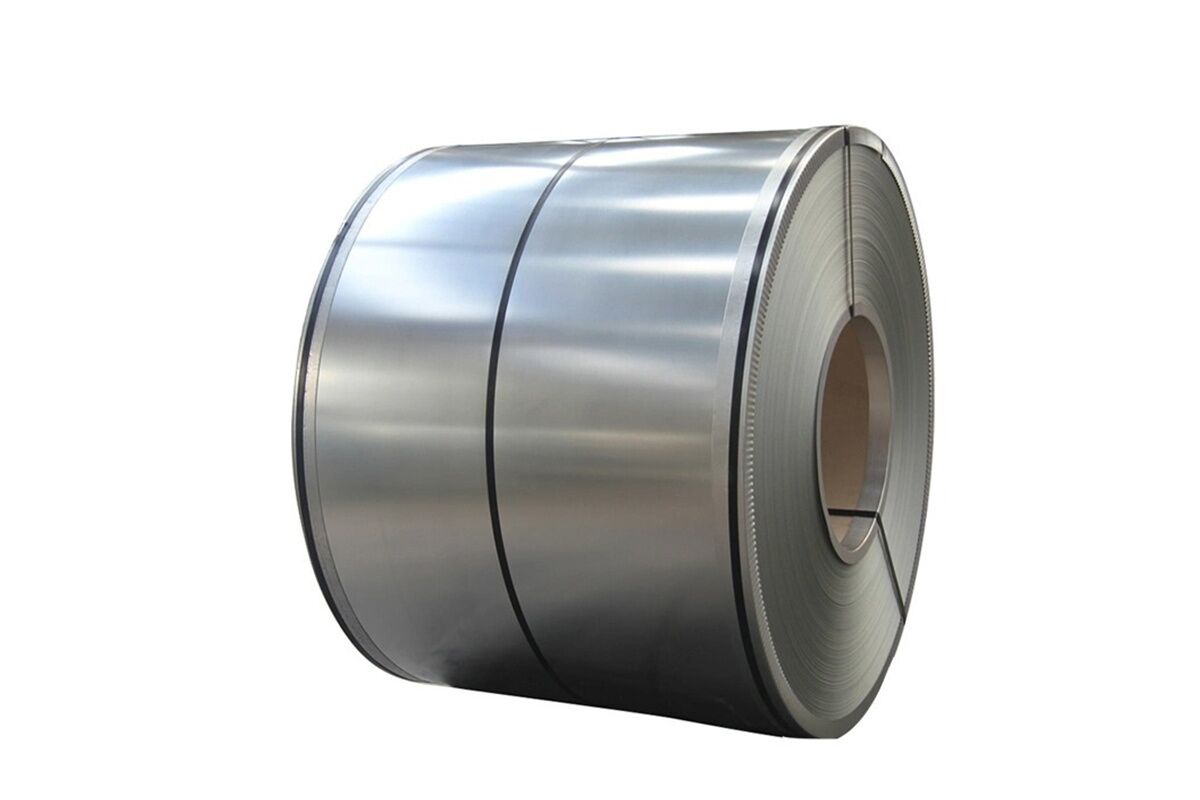

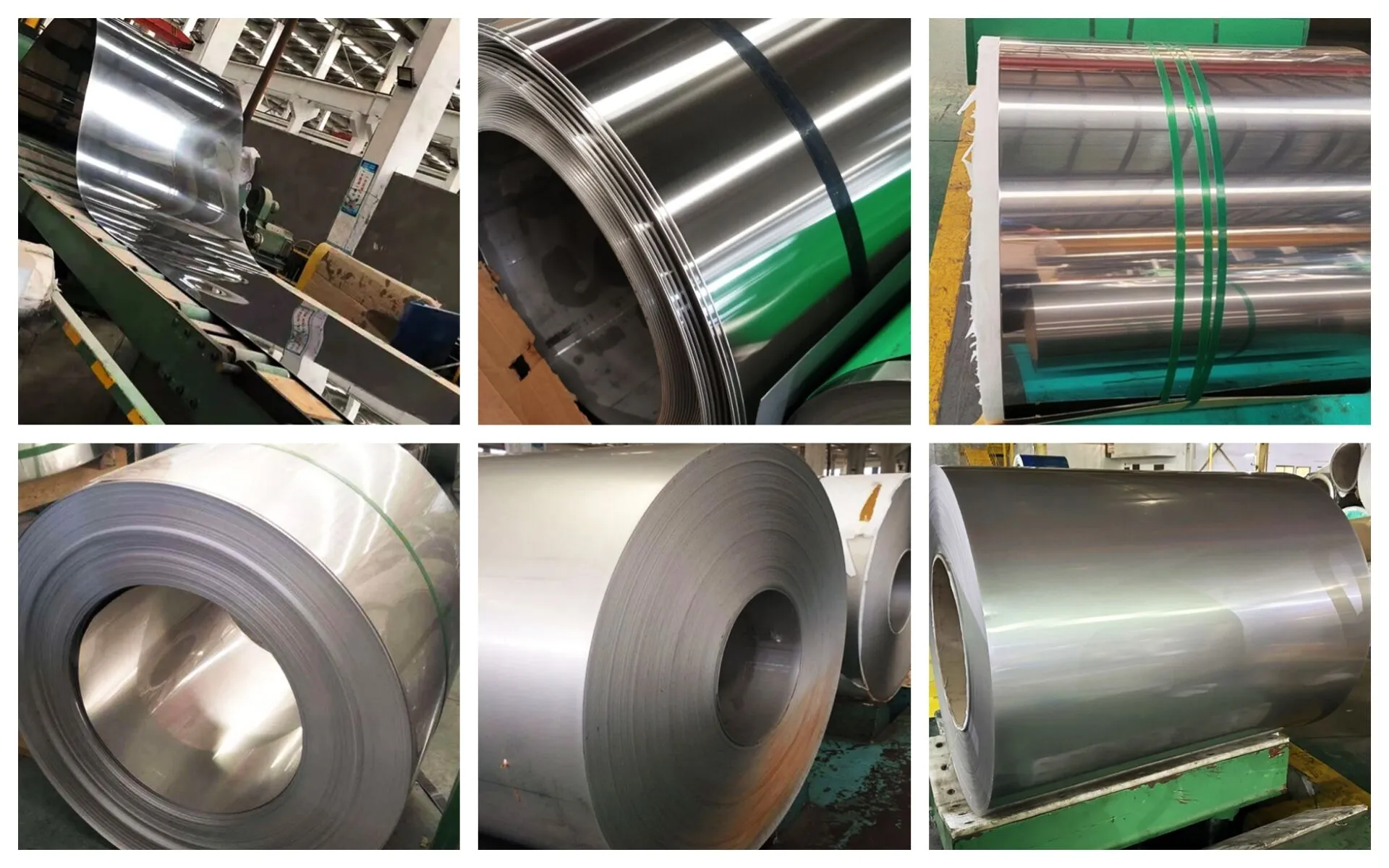

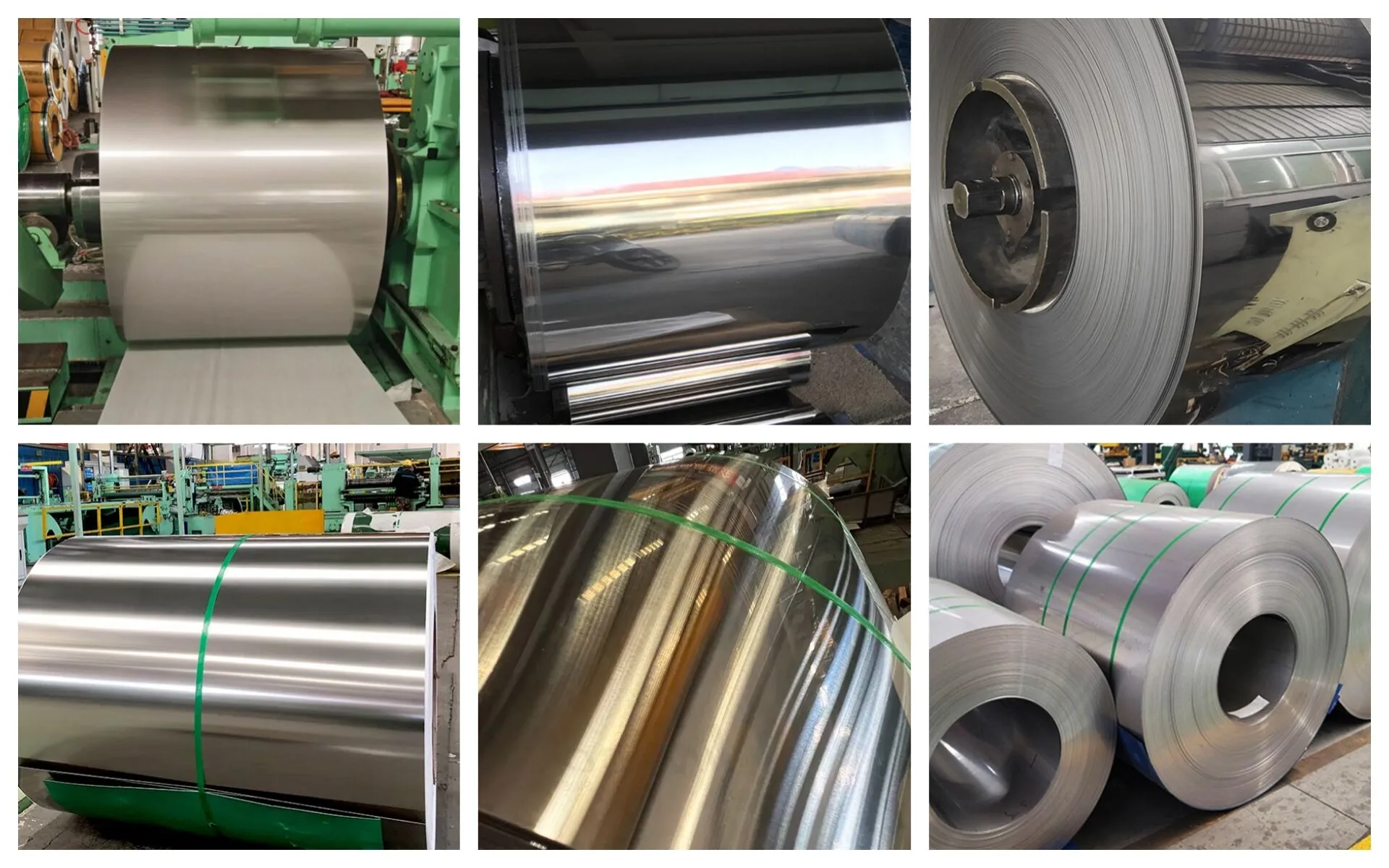

| Product Name | 316L Stainless Steel Coil |

| Place of Origin | Jiangsu, China |

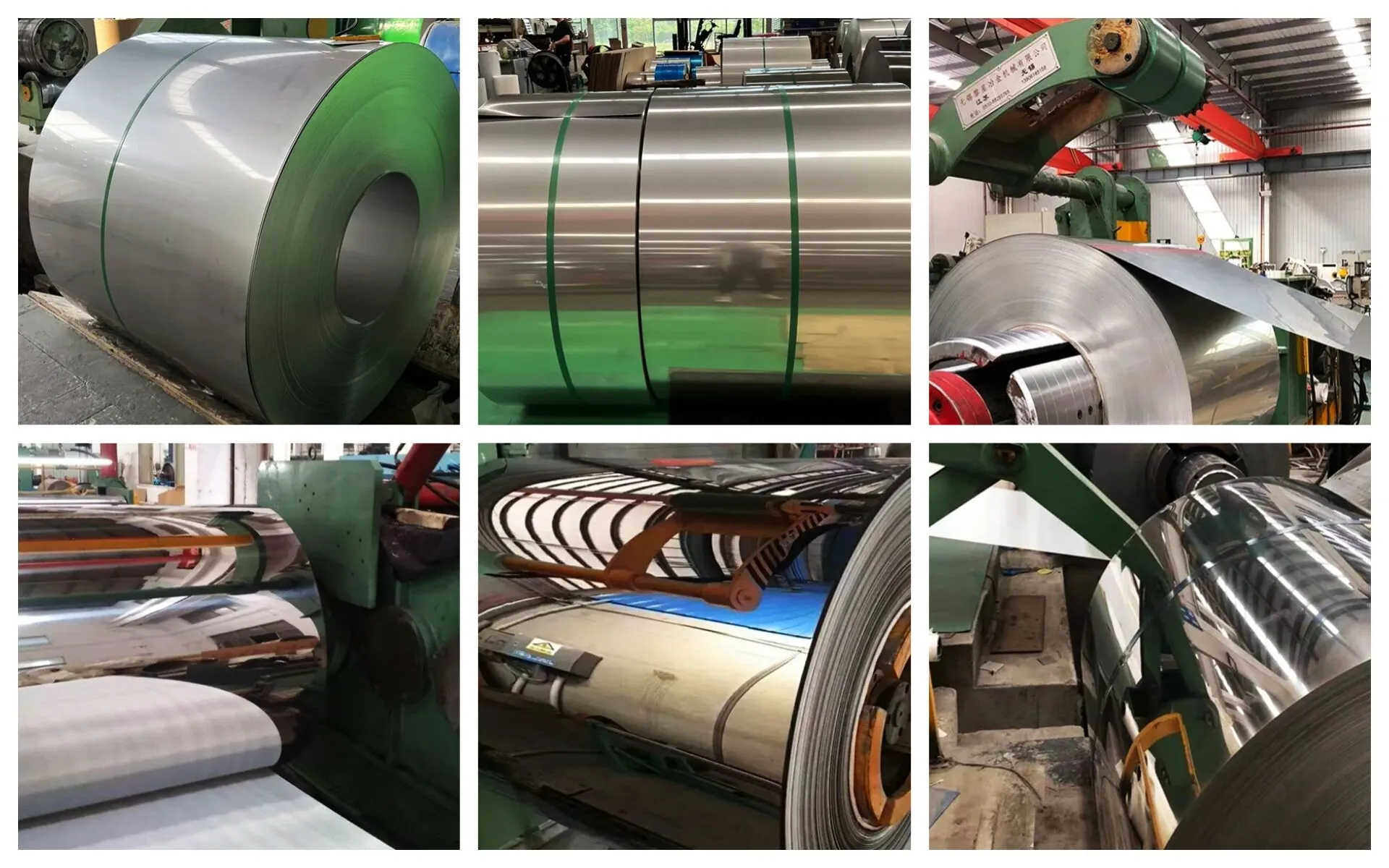

| Production Process | Starting from 316L stainless steel billets produced by steelmaking, it is initially formed by hot rolling, then precisely rolled to the target thickness by a cold rolling mill. Subsequently, annealing treatment is carried out to eliminate work hardening, followed by pickling to remove the surface oxide scale. Finally, it is coiled after processes such as leveling and slitting. |

| Execution Standards | Comply with GB/T 24511 – 2017 Stainless Steel and Heat – resisting Steel Sheets and Strips for Pressure Equipment, ASTM A240/A240M (American Society for Testing and Materials standards), EN 10088 – 2 (European standards), etc. |

| Chemical Composition | Carbon (C) ≤ 0.030%, Silicon (Si) ≤ 1.00%, Manganese (Mn) ≤ 2.00%, Phosphorus (P) ≤ 0.045%, Sulfur (S) ≤ 0.030%, Chromium (Cr): 16.00 – 18.00%, Nickel (Ni): 10.00 – 14.00%, Molybdenum (Mo): 2.00 – 3.00% (The actual composition is subject to the test report). |

| Types | Cold – rolled coils: High surface quality, good dimensional accuracy, high strength and hardness; Hot – rolled coils: Thicker in thickness, relatively lower in cost, suitable for occasions with low requirements for surface quality. |

| Thickness | Cold – rolled coils: 0.3mm – 3.0mm; Hot – rolled coils: 3.0mm – 12.0mm (Special thicknesses can be customized). |

| Width | 600mm – 1500mm (Customizable according to requirements). |

| Inner Diameter | Commonly 508mm (12 inches), 610mm (24 inches), customizable. |

| Weight | Conventional single – coil weight is 1 – 10 tons, negotiable. |

| Surface Treatments | 2B surface: Smooth with a slight luster, suitable for further processing; BA surface: Mirror – bright, often used in industries with high surface requirements such as food and medical; Matte surface: With a fine matte texture, wear – resistant and aesthetically pleasing; Colored coating: Endowed with different colors through processes such as titanium plating and spraying, used in the decorative field. |

| Corrosion Resistance | With the presence of molybdenum, it has strong resistance to corrosive media such as chloride ions, sulfuric acid, and hydrochloric acid, suitable for highly corrosive environments such as the chemical and marine industries. |

| Processability | It can be processed by shearing, stamping, bending, welding, etc., making it easy to fabricate various components. |

| Strength and Toughness | It has both good strength and toughness, and can withstand certain pressure and deformation. |

| High – temperature Resistance | It can still maintain stable performance in high – temperature environments, with a maximum service temperature of up to about 600°C. |

| Food and Beverage | Used to manufacture food processing equipment, storage containers, etc., meeting hygiene standards. |

| Chemical Industry | Used to manufacture corrosion – resistant equipment such as reaction kettles, pipelines, and storage tanks. |

| Architectural Decoration | Processed into decorative panels, curtain wall materials, metal products, etc. |

| Medical Equipment | Used to manufacture medical devices, medical storage appliances, etc. |

| Home Appliance Manufacturing | Used to produce the casings and internal components of home appliances such as refrigerators and washing machines. |

| Quality Assurance | Provide material certificates, mechanical property test reports, chemical composition analysis reports, and support third – party testing. |

| Packaging Method | The inner layer is wrapped with moisture – proof paper or plastic film, and the outer layer is bundled and fixed with iron sheets or steel strips, supported by wooden pallets to prevent moisture and scratches during transportation. |

| Delivery Time | 3 – 7 days for regular specifications, 7 – 15 days for customized specifications. |

| Payment Terms | T/T (Telegraphic Transfer), L/C (Letter of Credit), etc., negotiable. |

| After – sales Service | Provide technical consultation. In case of quality problems, negotiate for return, replacement, or replenishment. |

Physical and chemical properties:

Physical and chemical properties:

Physical properties

Appearance:

Usually presents a silver-grey metallic luster, with a smooth surface. Depending on the processing technology and surface treatment methods, it can have different glossiness and texture.

Density: About 7.98 g/cm³, compared with other common metals, it is a material with a higher density.

Melting point:

The melting point is around 1370-1400℃, with a high melting point, which enables it to maintain a stable solid state under high temperature environment.

Coefficient of thermal expansion: In the range of room temperature to 100℃, the thermal expansion coefficient is about 16.0×10⁻⁶/℃. As the temperature changes, its size will expand or contract to a certain extent.

Magnetism:

316L stainless steel is an austenitic stainless steel. It is non-magnetic or weakly magnetic under normal circumstances, but it may produce certain magnetism after cold working deformation.

Chemical properties

Corrosion resistance:

Due to the high content of chromium (Cr), nickel (Ni) and molybdenum (Mo) elements, 316L stainless steel has excellent corrosion resistance. Chromium forms a dense protective film of chromium oxide on the surface of stainless steel, which prevents oxygen and other corrosive substances from contacting the metal matrix, thereby preventing rust and corrosion. The addition of molybdenum further improves its resistance to pitting and crevice corrosion in chloride environments, making it particularly suitable for environments that come into contact with chlorine-containing media such as seawater and salt water.

Antioxidation:

At room temperature, 316L stainless steel can resist the oxidation of oxygen in the air. In high temperature environments, it can also form a stable oxide film with good antioxidation properties, but as the temperature rises, the antioxidation ability will gradually decrease.

Chemical stability:

It has good stability to most chemicals such as acids, alkalis, and salts. In some common acidic media, such as dilute sulfuric acid and phosphoric acid, it has good corrosion resistance, but in strong oxidizing acids (such as concentrated sulfuric acid and concentrated nitric acid), its corrosion resistance will be limited to a certain extent. In alkaline media, 316L stainless steel also shows good tolerance.

Intergranular corrosion resistance: 316L stainless steel has a low carbon content and contains stabilizing elements such as titanium (Ti) or niobium (Nb), which can effectively prevent intergranular corrosion during welding or high-temperature heating, improve the material’s welding performance and corrosion resistance in some special environments.

Application:

316L stainless steel coil is widely applied across multiple industries. In the chemical industry, it is used to manufacture reaction vessels, pipelines, and storage tanks, thanks to its excellent resistance to strong acids, alkalis, and other corrosive substances. In the food and beverage sector, it is an ideal material for food processing equipment and storage containers, ensuring hygiene and safety. In marine engineering, it withstands seawater corrosion, suitable for shipbuilding and offshore structure construction. In architecture, it can be fabricated into decorative panels, curtain walls, and railings, combining aesthetics with durability. Additionally, in the medical field, it meets strict requirements for manufacturing medical devices due to its biocompatibility and corrosion resistance.