PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

304 stainless steel bar

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product Details Table:

| Item | Details |

|---|---|

| Product Name | 304 stainless steel bar |

| Material Type | Austenitic stainless steel; 18% Cr, 8% Ni, C≤0.08%, with Fe, Mn, Si, etc. |

| Execution Standard | GB/T 1220, ASTM A276/A484, EN 10088-3, JIS G4303 |

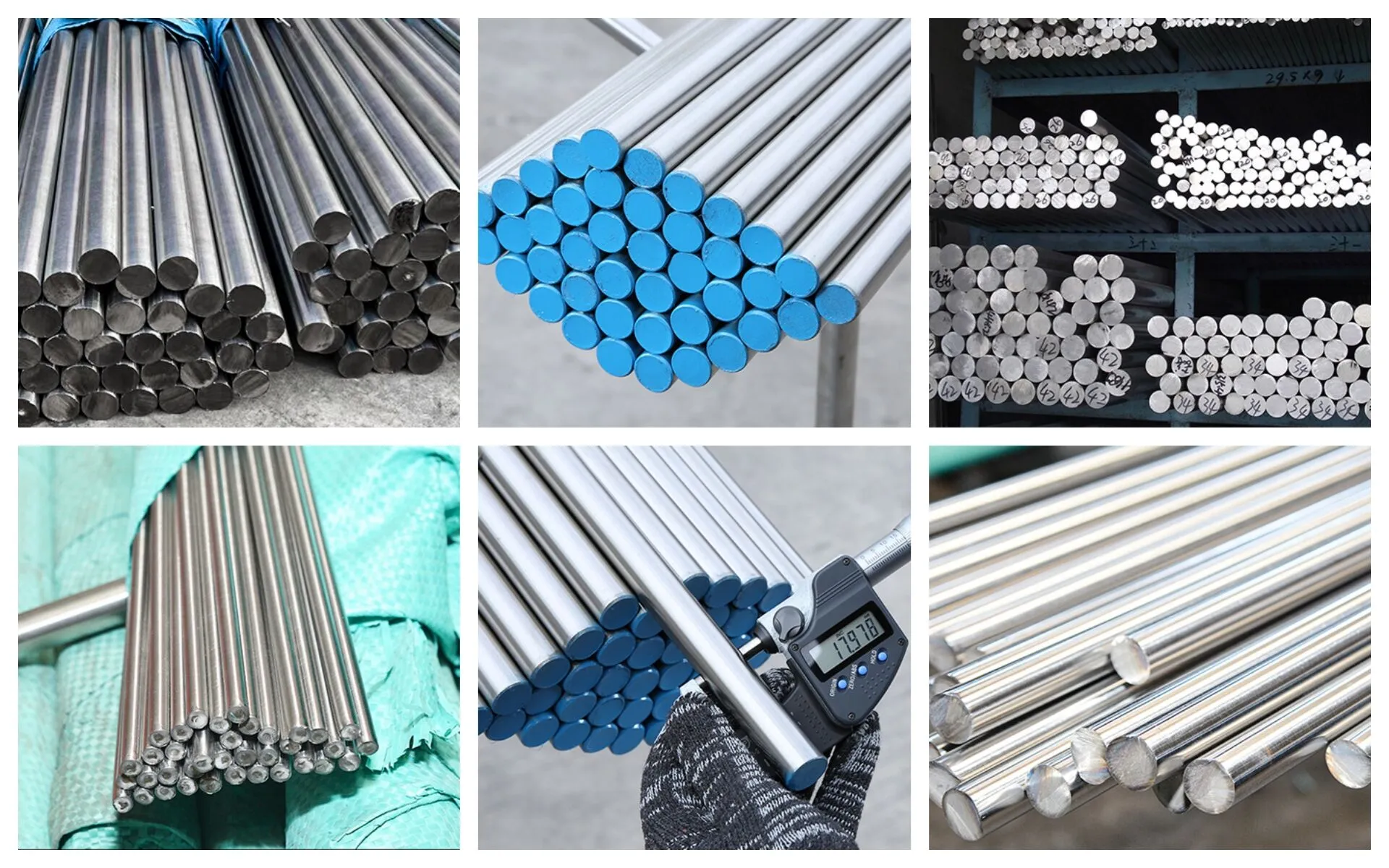

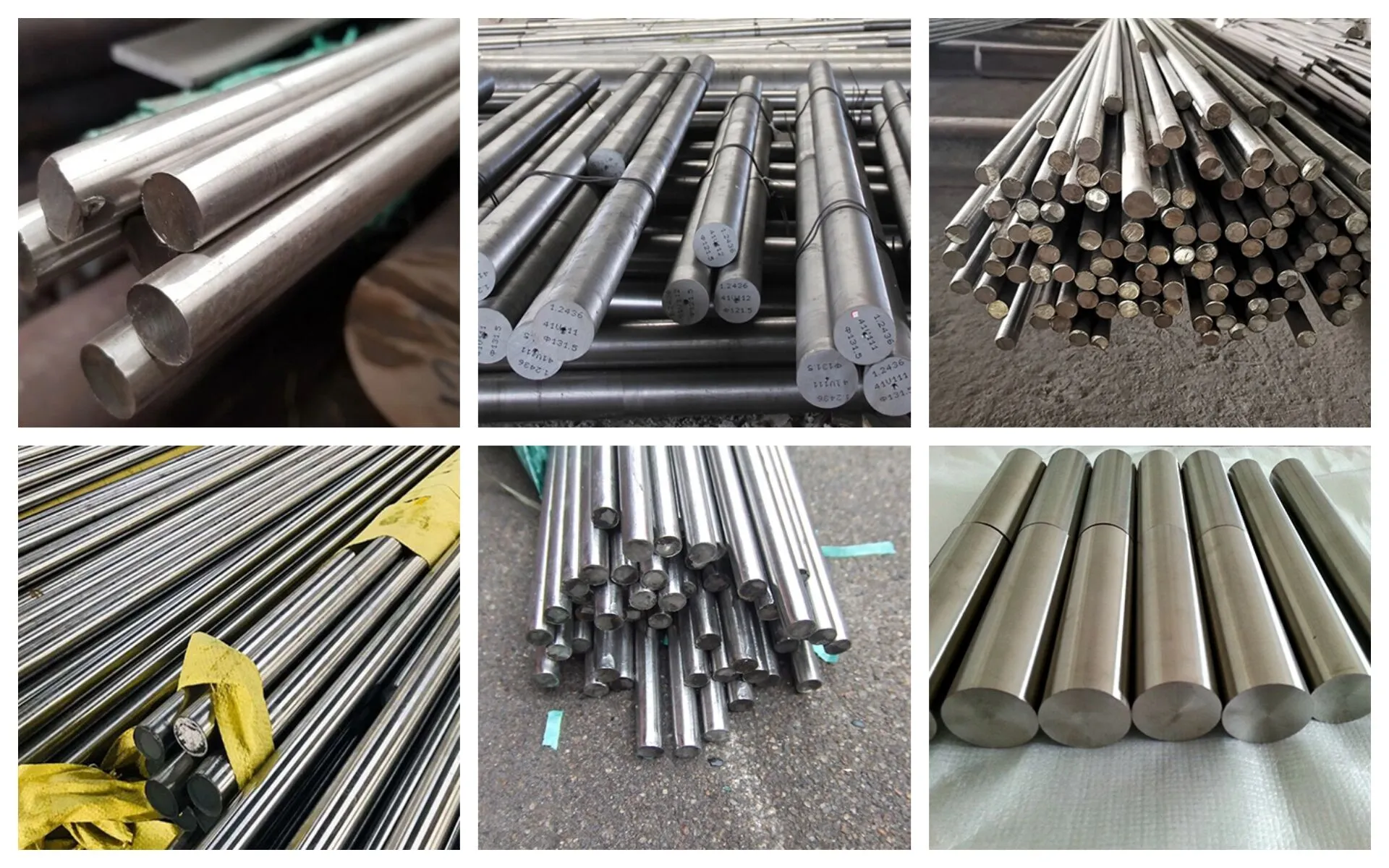

| Specifications | Round: Φ3-300mm; Square: 3-150mm side; Hex: 3-120mm across flats; Flat: 3-50×10-200mm; 6m standard length, customizable |

| Surface Treatment | Black (hot-rolled), Bright (cold-drawn), Mirror, Pickled, Oiled |

| Mechanical Properties | Tensile≥520MPa; Yield≥205MPa; Elongation≥40%; Density 7.93g/cm³ |

| Physical Characteristics | Non-magnetic (weak magnetism possible after cold work); -196℃-800℃, 17.3×10⁻⁶/℃ thermal expansion |

| Corrosion Resistance | Resistant to atmosphere, water, and weak acids/alkalis; good in oxidizing acids, but less resistant to chlorides |

| Typical Applications | Machinery, Architecture, Food & Medical, Kitchenware, Electronics |

| Processing Technology | Hot rolling, Cold drawing, Forging, Machining |

| Packaging Method | Moisture-proof paper + plastic film, protective sleeves, bundled or cased |

| Delivery Period | Regular: 3-7 days; Custom: 7-15 days |

| Quality Certification | ISO 9001, SGS, RoHS |

Physical and chemical properties:

Physical properties

Appearance:

Usually presents a silver-gray metallic luster, smooth surface, and good texture.

Density:

The density is 7.93g/cm³, which is medium density compared with other common metals.

Magnetism:

Under normal circumstances, 304 stainless steel bars are non-magnetic, but after cold working and deformation, they may produce weak magnetism.

Melting point:

The melting point is about 1398-1454℃, with a high melting point, and can maintain good stability in high temperature environments.

Coefficient of thermal expansion:

In the temperature range of 20-100℃, the thermal expansion coefficient is about 17.3×10⁻⁶/℃, with good thermal expansion performance and can adapt to a certain degree of temperature changes.

Thermal conductivity:

The thermal conductivity is 16.2W/(m・K), which is relatively low and has certain thermal insulation properties.

Conductivity:

The electrical conductivity is about 1.4×10⁶ S/m, with good electrical conductivity.

Chemical properties

Corrosion resistance:

This is one of the most outstanding chemical properties of 304 stainless steel bars. It contains about 18% chromium and about 8% nickel. Chromium can form a dense chromium oxide film on the surface of stainless steel. This passivation film can prevent oxygen, water and other corrosive media from contacting the metal matrix, thereby effectively preventing rust and corrosion. 304 stainless steel bars have excellent corrosion resistance in the atmosphere, water and weak acid and alkali environments. It can also maintain good stability in oxidizing acids (such as nitric acid, concentration ≤65% and below the boiling point), alkaline solutions and most organic acids.

Oxidation resistance:

304 stainless steel bars have good oxidation resistance in normal to high temperature environments. The oxide film on its surface can prevent further oxidation reactions to a certain extent, so that it can maintain good performance in high temperature environments. However, in high temperature, high humidity and environments containing specific corrosive media, its oxidation resistance may be affected to a certain extent.

Chemical stability:

304 stainless steel bars have high stability in general chemical environments and are not easy to react chemically with common chemicals. However, under certain conditions, such as when encountering strong oxidizing acids (such as concentrated sulfuric acid, concentrated nitric acid) or solutions containing a large amount of chloride ions, its corrosion resistance may decrease and corrosion reactions may occur.