PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

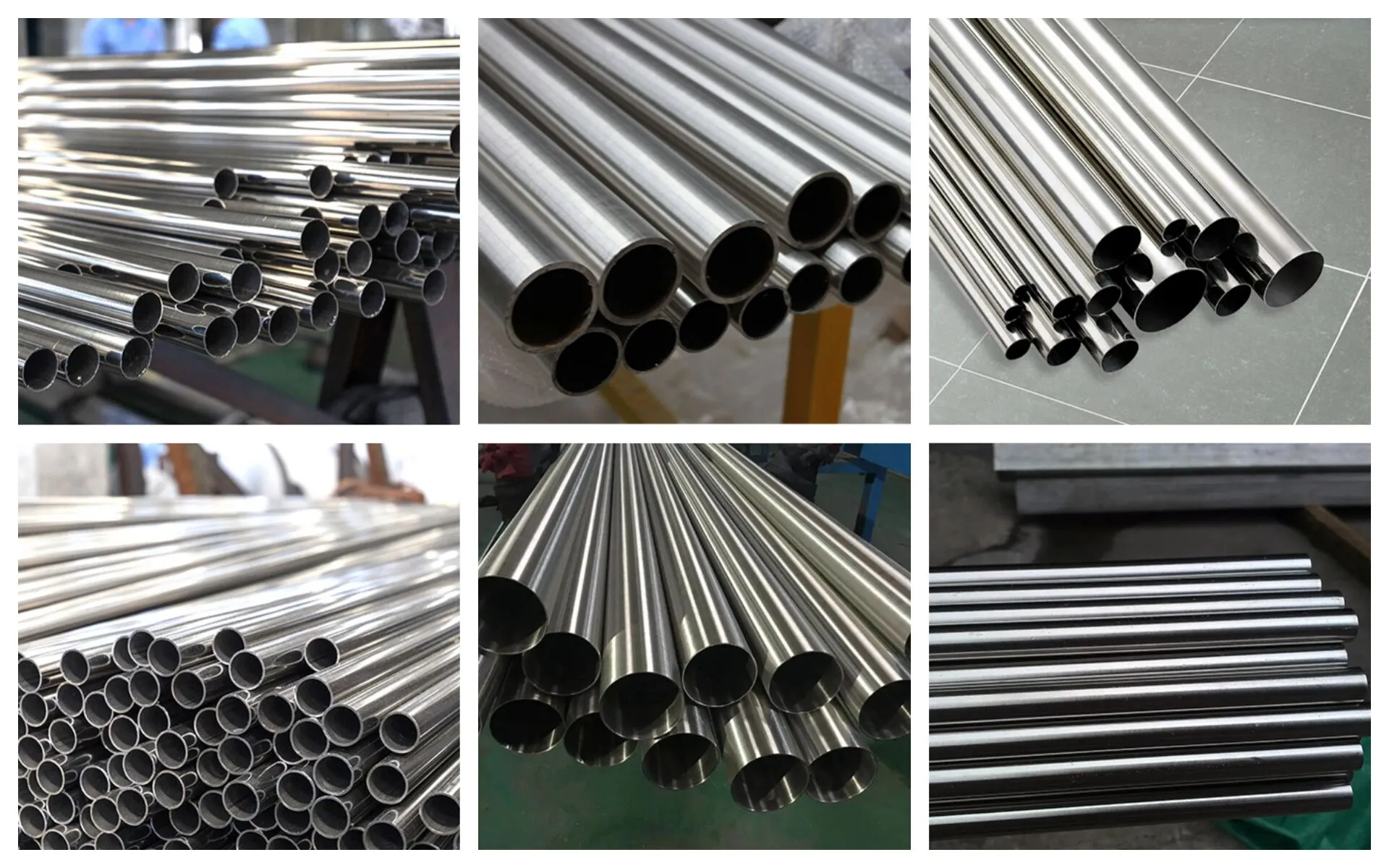

304 Stainless steel pipe

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details table:

| Product Name | 304 Stainless Steel Pipe |

|---|---|

| Steel type | 304 Austenitic Stainless Steel Pipe |

| Other | Cutting, bending, welding, polishing, or as customer’s request |

| Size | Round Pipe: Outer diameter 6 – 530mm, Wall thickness 0.3 – 10mm; Square Pipe: Side length 10×10 – 200×200mm, Wall thickness 0.3 – 8mm; Rectangular Pipe: Side length 10×20 – 150×100mm, Wall thickness 0.3 – 8mm; Length: Standard 6m, custom lengths available |

| Material grade | 06Cr19Ni10 (GB), 304 (ASTM), 1.4301 (EN) |

| Standard | GB/T 14976, ASTM A312, ASTM A213, DIN 17458, JIS G3459 |

| Surface | 2B, BA, No.4 finish, hairline finish, mirror polish, sandblasting, pickling passivation |

| MOQ | 1 Ton |

| Size Tolerance | Outer diameter: ±0.5mm; Wall thickness: ±0.05mm |

| Package | Wrapped with moisture – proof paper and plastic film, edge protection with steel corners; packed in wooden cases or on pallets. Special packaging can be customized |

| Certificate | ISO 9001, SGS, CE |

| Price terms | EXW/FOB/CIF/CFR, other terms negotiable |

| Delivery Time | Regular specification: 7 – 15 days; Customized specification: 15 – 30 days |

| Payment terms | 30% T/T deposit, 70% T/T before shipment; L/C at sight; Trade Assurance |

| Application Range | Widely used in 1.) Architectural decoration: Handrails, railings, curtain wall structures; 2.) Food and beverage industry: Processing equipment, pipelines, storage tanks; 3.) Chemical and pharmaceutical industry: Corrosion – resistant pipelines, reaction vessels; 4.) Mechanical manufacturing: Structural components, hydraulic pipes; 5.) Automobile and shipbuilding: Exhaust systems, internal pipelines |

| Advantages | 1. Factory – direct prices with comprehensive trading services. 2. Rigorous quality control system to ensure zero – defect delivery. 3. 24 – hour quick response and 48 – hour solution guarantee. 4. Accept small trial orders before large – scale cooperation |

Physical and chemical properties:

Physical and chemical properties:

Physical properties

Appearance:

Density: About 7.93g/cm³, the relative density is relatively large, which makes 304 stainless steel tube have a certain weight and texture.

Melting point:

Coefficient of thermal expansion: The average linear expansion coefficient is about 17.3×10⁻⁶/℃ (in the range of 20-100℃), and its size will expand or shrink to a certain extent as the temperature changes.

Thermal conductivity:

Conductivity: It has a certain conductivity, but not as good as copper, aluminum and other metals. Its conductivity is about 20% of copper.

Chemical properties

Corrosion resistance:

Oxidation resistance:

Chemical stability:

Application:

304 stainless steel pipes are widely used in multiple fields due to their excellent corrosion resistance, strength and hygienic characteristics. In architectural decoration, they are often used to make railings, handrails and curtain wall frames, which are both beautiful and can resist wind and rain erosion. In the food and beverage industry, they are used to manufacture processing equipment, conveying pipelines and storage tanks to meet hygienic standards and prevent food contamination. In the medical field, due to being clean, non-toxic and easy to disinfect, they are used in pharmaceutical equipment and medical gas pipelines. In mechanical manufacturing, as hydraulic and pneumatic pipelines and mechanical structural parts, they ensure the stable operation of equipment. In addition, in the fields of water treatment and environmental protection, they are used to transport corrosive liquids and install purification equipment to effectively extend service life.