PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Stainless steel pipe

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details table:

| Items | Details |

|---|---|

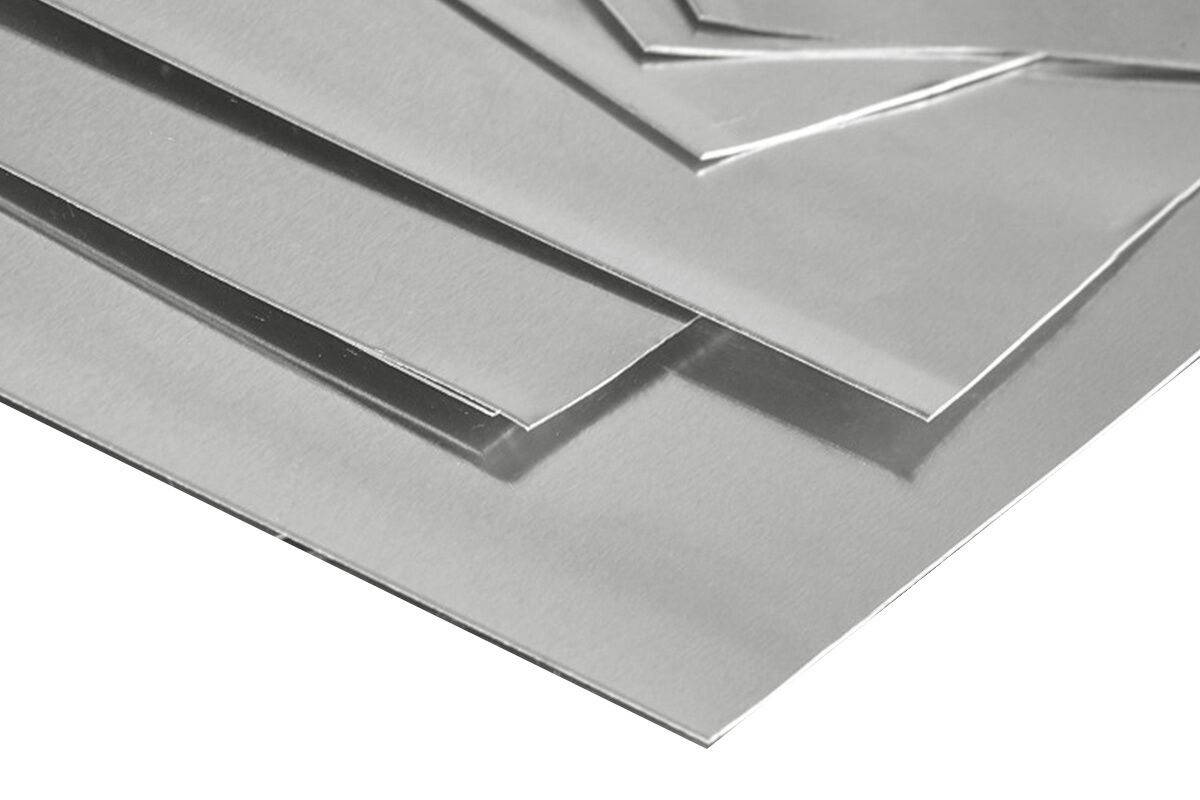

| Product Name | 316L Stainless steel plate |

| Place of Origin | Jiangsu, China |

| Production Process | Steelmaking is carried out using an electric arc furnace or a converter. After processes such as refining and continuous casting, steel billets are produced. Then, they are rolled through hot rolling or cold rolling processes. Finally, treatment processes such as annealing, pickling, and leveling are carried out to obtain the required performance and surface quality. |

| Execution Standards | Comply with GB/T 24511-2017 Stainless Steel and Heat-resisting Steel Plates and Strips for Pressure Equipment, ASTM A240/A240M (Standard of the American Society for Testing and Materials), EN 10088-2 (European standard), etc. |

| Chemical Composition | Carbon (C) ≤ 0.030%, Silicon (Si) ≤ 1.00%, Manganese (Mn) ≤ 2.00%, Phosphorus (P) ≤ 0.045%, Sulfur (S) ≤ 0.030%, Chromium (Cr): 16.00 – 18.00%, Nickel (Ni): 10.00 – 14.00%, Molybdenum (Mo): 2.00 – 3.00% (The specific composition ratio is subject to the actual product). |

| Types | Hot-rolled plate: Thicker in thickness, with relatively poorer surface quality compared to cold-rolled plates, suitable for occasions with low surface requirements and high strength requirements. Cold-rolled plate: Thinner in thickness, with high surface finish and dimensional accuracy, suitable for occasions with high requirements for surface quality and dimensional accuracy. |

| Thickness | Hot-rolled plate: 3.0mm – 60.0mm Cold-rolled plate: 0.3mm – 6.0mm (Special thicknesses can be customized). |

| Width | 1000mm, 1219mm, 1500mm, 2000mm, etc. (Customizable) |

| Length | 2000mm, 2438mm, 3000mm, 6000mm, etc. (Customizable) |

| Surface Treatment | 2B surface: Smooth with a slight luster, commonly used as a base plate for stamping, stretching, and other processing. BA surface: Bright surface with high reflectivity, often used in the food processing and kitchen equipment industries. NO.1 surface: After hot rolling, heat treatment, and pickling treatment, with a rough surface, suitable for industrial applications with low surface requirements. 8K mirror surface: High mirror effect with extremely high reflectivity, often used in the decoration industry. Brushed surface: The surface has a 丝状 texture, which is wear-resistant and beautiful, suitable for the decoration and home appliance industries. |

| Corrosion Resistance | Due to the presence of molybdenum, the 316L stainless steel plate has better corrosion resistance than the 304 stainless steel plate, especially in terms of resistance to chloride ion corrosion, and is suitable for industries such as marine environments, chemical engineering, and food and beverage. |

| High-temperature Resistance | It can maintain good mechanical properties in high-temperature environments, with a maximum service temperature of up to about 600°C. |

| Strength and Toughness | It has good strength and toughness and can withstand a certain amount of pressure and impact force, meeting the requirements of various engineering structures. |

| Processability | It can undergo various processing operations such as cutting, bending, welding, and stamping, and is easy to process and form to meet different design and usage requirements. |

| Food and Beverage Industry | Used for manufacturing food processing equipment, storage containers, pipelines, etc., in line with food hygiene standards. |

| Chemical Industry | Used for manufacturing corrosion-resistant equipment such as reaction kettles, heat exchangers, pipelines, and valves. |

| Marine Engineering | Suitable for offshore platforms, shipbuilding, etc., to resist seawater corrosion. |

| Architectural Decoration | Used for curtain walls, railings, handrails, elevator decorative panels, etc., which are beautiful and durable. |

| Medical Equipment | Used for manufacturing medical devices, surgical instruments, etc., with good biocompatibility and corrosion resistance. |

| Quality Assurance | Provide material certificates, mechanical property test reports, chemical composition analysis reports, etc., and support third-party testing. |

| Packaging Method | Wrapped with moisture-proof paper or plastic film, and bundled with wooden pallets or steel strips to prevent surface scratches and moisture during transportation. |

| Delivery Time | 3 – 7 days for regular specification orders; 7 – 15 days for customized specification orders. |

| Payment Terms | T/T (Telegraphic Transfer), L/C (Letter of Credit), etc., negotiable. |

| After-sales Service | Provide technical consultation and guidance. In case of product quality problems, negotiate for return, replacement, or replenishment. |

Physical properties and chemical properties:

Physical properties and chemical properties:

Physical Properties

Density: Approximately 7.98 g/cm³, which is relatively stable and helps in calculating the weight and volume in practical applications.

Melting Point: Ranges from 1370 – 1400 °C, enabling it to maintain its structural integrity in high – temperature environments to a certain extent.

Thermal Conductivity: At room temperature, the thermal conductivity is about 16.3 W/(m·K). It has relatively low thermal conductivity compared to some metals, which can play a role in heat insulation and energy conservation in some applications.

Electrical Resistivity: The electrical resistivity is approximately 7.2 × 10⁻⁷ Ω·m, showing certain resistance to the flow of electric current, which is of practical significance in electrical and electronic applications.

Mechanical Properties: It has good strength and toughness. The yield strength is generally not less than 175 MPa, the tensile strength is not less than 480 MPa, and the elongation after fracture is not less than 40%. These properties allow it to withstand a certain amount of pressure and impact force.

Chemical Properties

Corrosion Resistance: The addition of molybdenum (Mo) significantly improves its corrosion resistance, especially in resisting chloride – ion corrosion. It has excellent resistance to various corrosive media such as seawater, salt solutions, and some organic acids, and is suitable for use in harsh chemical environments. Oxidation Resistance: In normal atmospheric environments, it can form a dense oxide film on its surface, which can prevent further oxidation and rust, and maintain good surface quality and performance.

Chemical Stability: It has good chemical stability and is less likely to undergo chemical reactions with common chemical substances. It can maintain its chemical composition and properties unchanged in a wide range of temperature and humidity conditions, ensuring the reliability and durability of the material in practical applications.

Application:

316L Stainless steel plate finds extensive application across multiple sectors. In the chemical industry, it is used to construct reaction vessels, pipelines, and storage tanks due to its excellent resistance to corrosive chemicals. In the food and beverage industry, it is ideal for manufacturing processing equipment, storage containers, and conveyor belts, meeting strict hygiene standards. In marine engineering, it is utilized in shipbuilding and offshore platforms, enduring seawater corrosion. In architecture, it is employed for decorative elements, handrails, and facades, combining aesthetics with durability. Additionally, in the medical field, it is used to make surgical instruments and medical implants because of its biocompatibility and resistance to bodily fluids.