PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

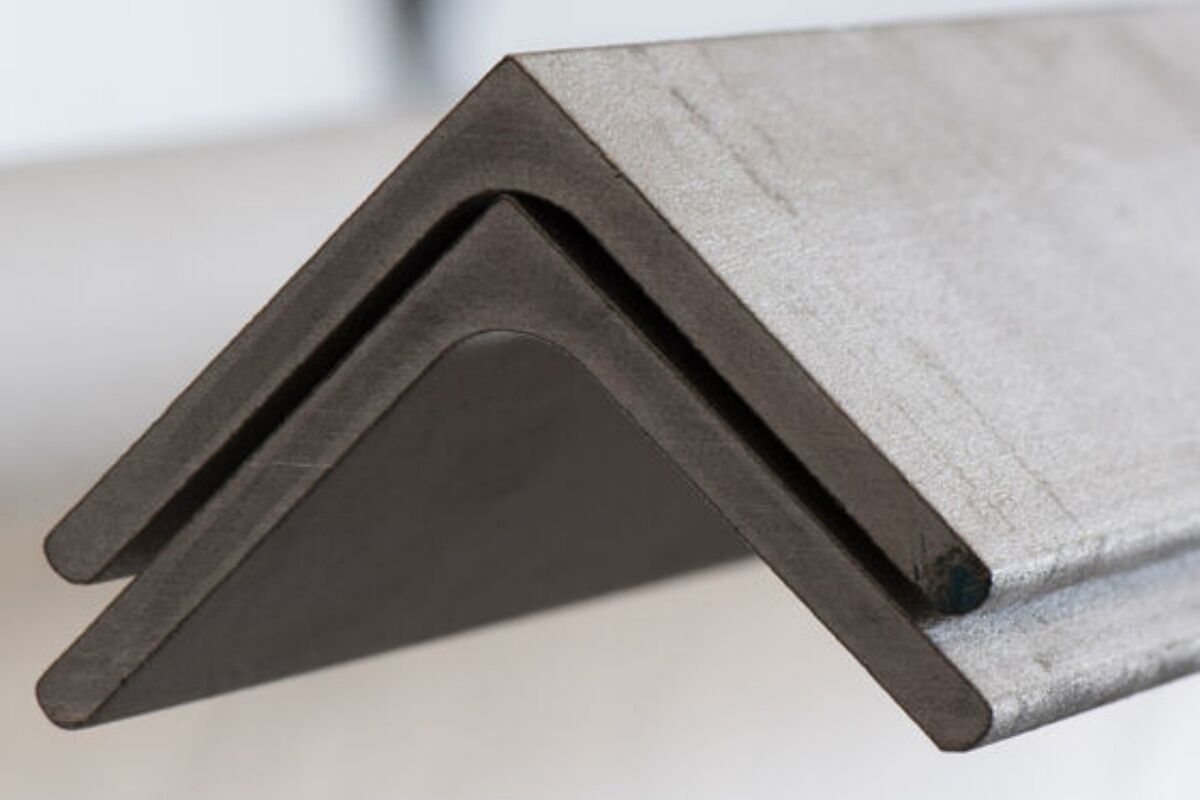

Carbon steel angle steel

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details table:

| Items | Details |

|---|---|

| Product Name | Carbon Steel Angle Steel |

| Place of Origin | Jiangsu, China |

| Production Process | Through the hot – rolling process, carbon steel billets are rolled by rolling mills at high temperatures to form angle steel. During the process, parameters such as temperature and rolling speed are strictly controlled to ensure the dimensional accuracy and quality of the angle steel. |

| Execution Standards | Comply with the domestic standard GB/T 706 – 2016 Hot – rolled Section Steel; internationally, refer to standards such as ASTM A36/A36M. |

| Base Materials | Commonly used carbon steel materials such as Q235 and Q345. Q235 has good plasticity, toughness, and weldability, and is widely used in general engineering structures; Q345 has higher strength and is suitable for occasions with high requirements for structural strength. |

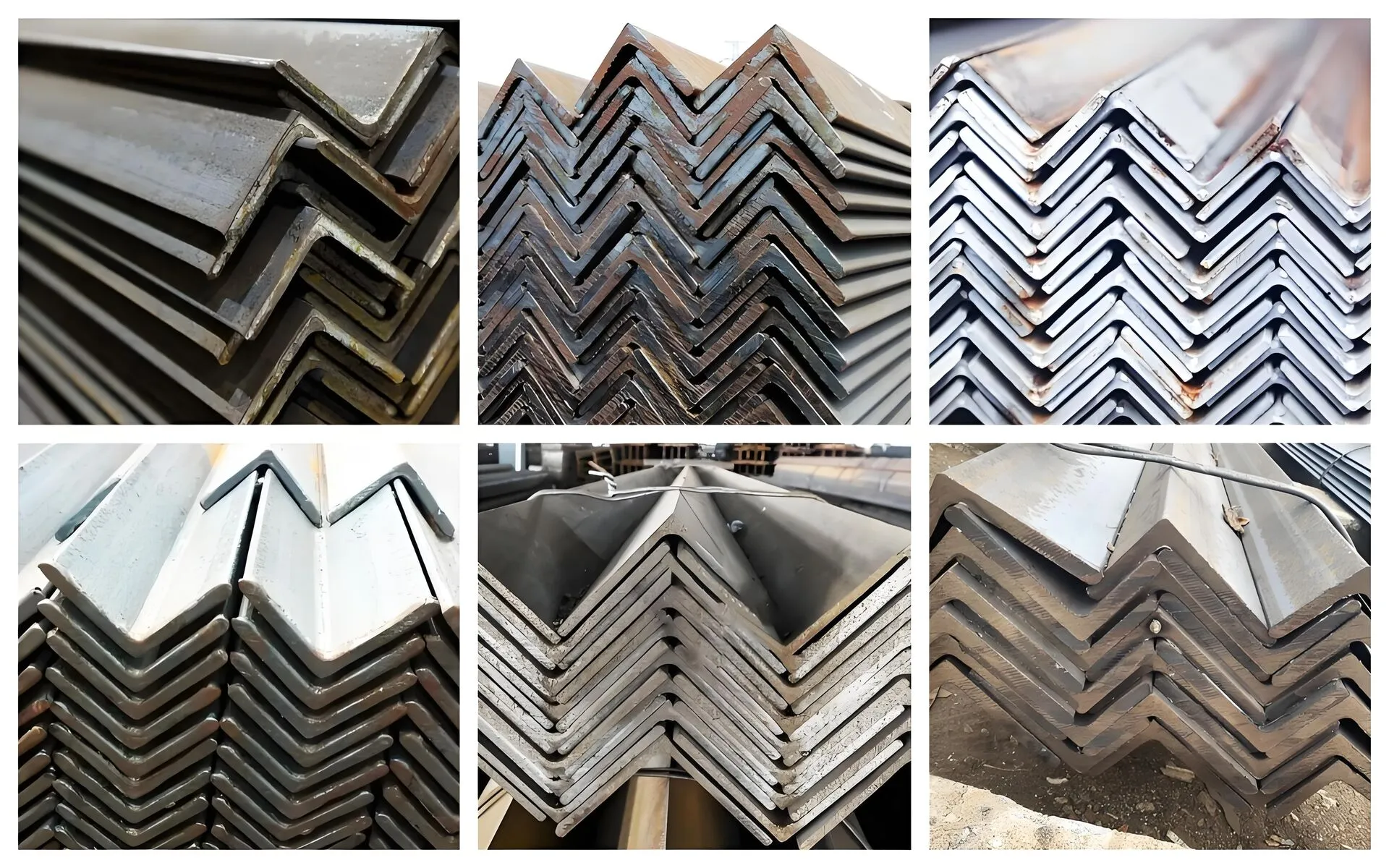

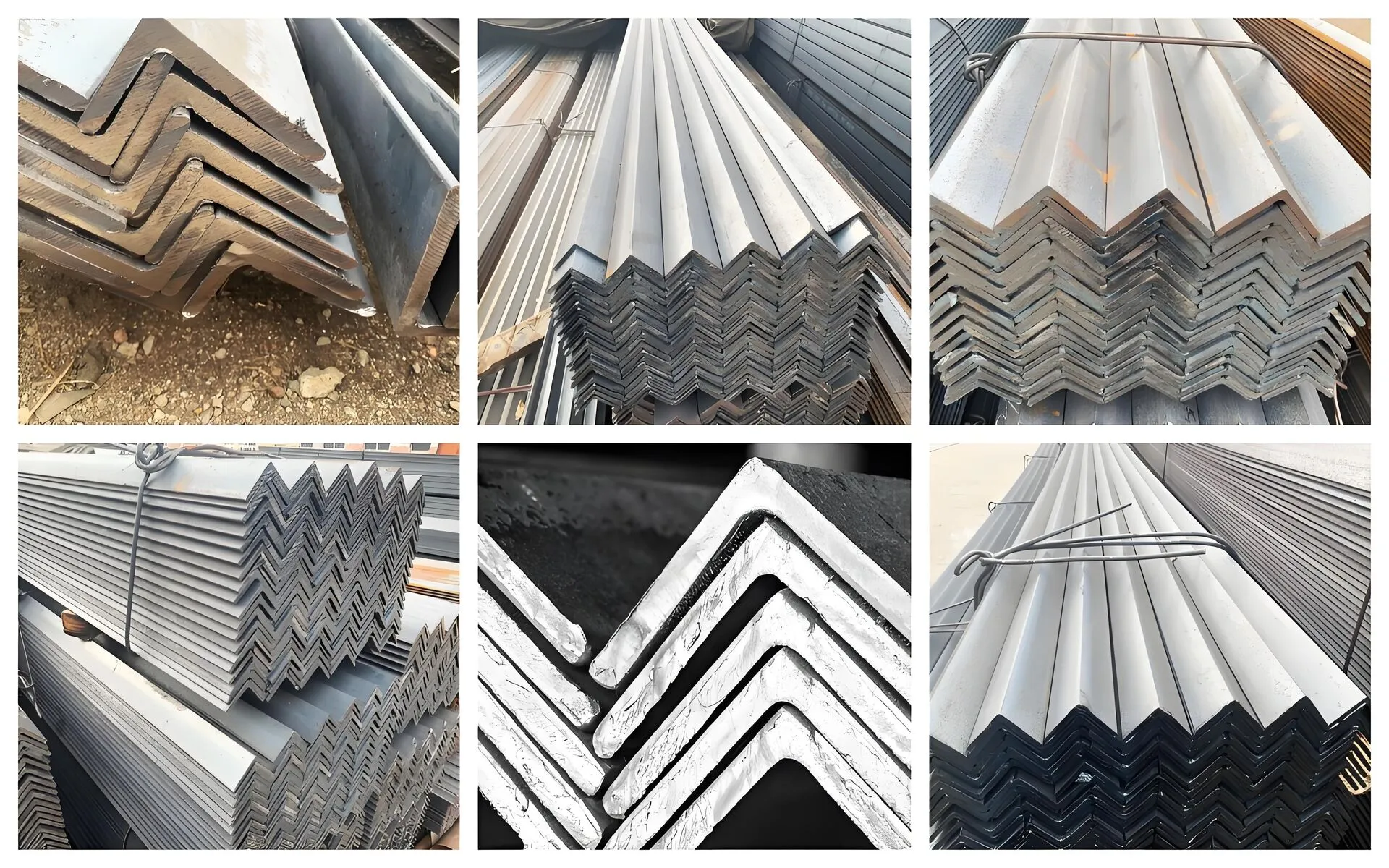

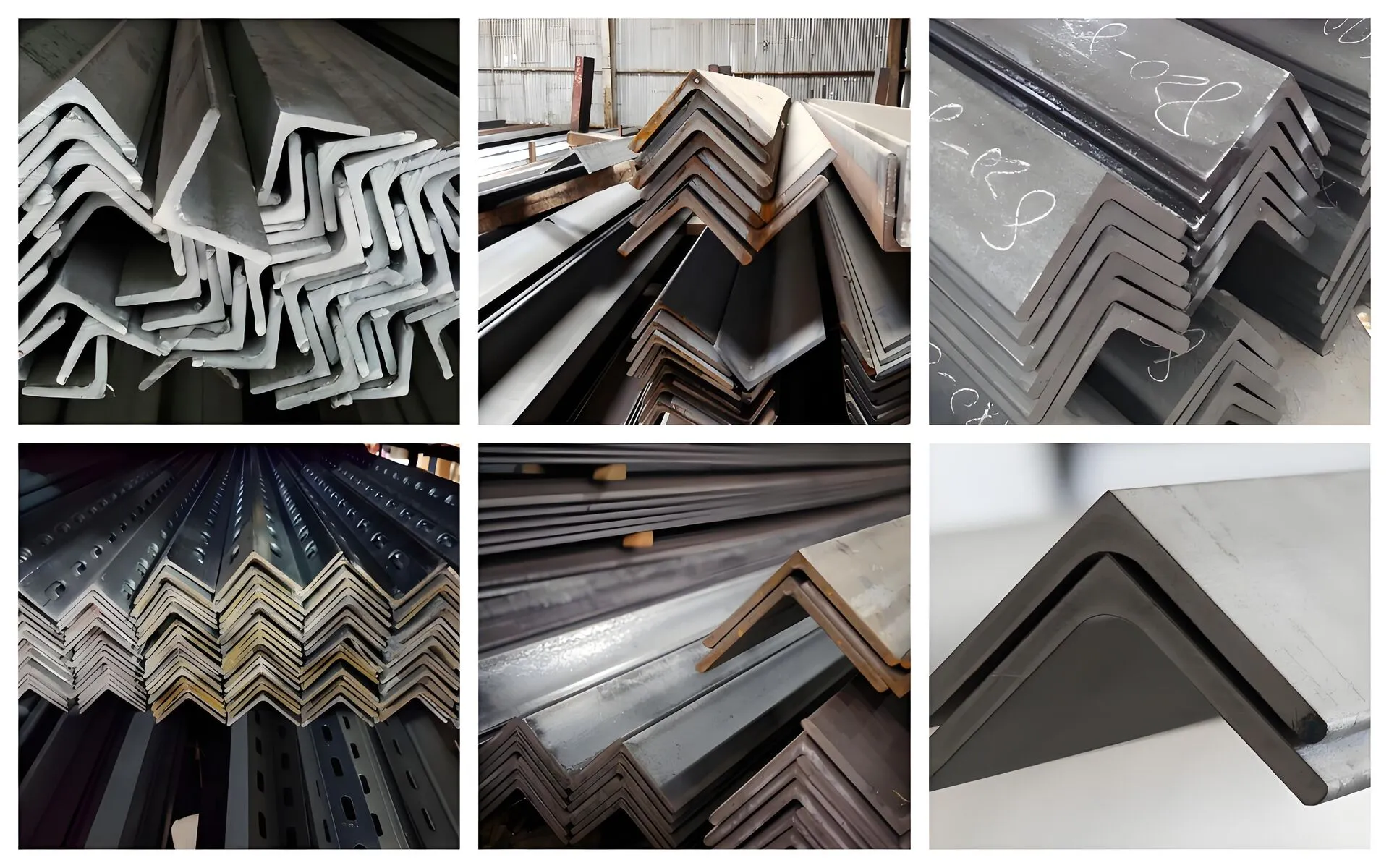

| Types | Equal – angle steel; Unequal – angle steel |

| Specification Range | For equal – angle steel, the side width ranges from 20mm to 200mm, and the side thickness ranges from 3mm to 20mm; for unequal – angle steel, the long – side width ranges from 25mm to 200mm, the short – side width ranges from 16mm to 125mm, and the side thickness ranges from 3mm to 16mm (special specifications can be customized). |

| Length | Conventional lengths are 6m, 9m, and 12m. Other lengths can be customized according to requirements. |

| Surface Treatment | Black material (original rolled surface): Low cost, suitable for general indoor use or occasions with low requirements for appearance; Galvanized treatment (hot – dip galvanizing, cold galvanizing): Hot – dip galvanizing has a thick zinc layer and strong corrosion resistance, suitable for outdoor and humid environments; cold galvanizing has a smoother and more beautiful surface, used for indoor decoration and occasions with low requirements for zinc layer thickness; Painting treatment: Different color paints can be selected according to requirements to enhance decorativeness and corrosion resistance. |

| Strength and Toughness | It has good strength and toughness, and can withstand certain pressure, tension, and impact force, meeting the mechanical performance requirements of various structural components. |

| Machinability | It is easy to perform processing operations such as cutting, welding, drilling, and bending, which is convenient for secondary processing at the construction site or factory to adapt to different engineering designs. |

| Economy | Compared with some special alloy steels, carbon steel angle steel has a more affordable price and high cost – performance ratio. It is widely used in various construction and industrial projects, effectively controlling costs. |

| Construction Industry | As a support for building structures, it is used to build house frames, steel – structure factories, bridges, etc., bearing the load of buildings; it is also used to make decorative parts such as door and window frames and stair handrails. |

| Machinery Manufacturing | It is used to manufacture machine frames, equipment supports, conveyor line tracks, etc., providing stable structural support for mechanical equipment. |

| Power Engineering | It is used to make transmission towers, substation structures, etc., ensuring the stable and safe operation of power facilities. |

| Hardware Products | It is used to make daily hardware products such as shelves, fences, and ladders, meeting the needs of storage, protection, and climbing operations. |

| Others | It is also widely used in fields such as shipbuilding and the construction of agricultural facilities (such as greenhouse frames). |

| Quality Assurance | Provide material certificates and mechanical property inspection reports, and support third – party inspection to ensure that product quality meets the standards. |

| Packaging Methods | Bare bundling: Suitable for large – volume orders and short – distance transportation. The angle steel is tightly bundled into bundles with steel strips; Moisture – proof paper + steel strip bundling: The angle steel is wrapped with moisture – proof paper and then bundled with steel strips to prevent rusting due to moisture during transportation, suitable for long – distance transportation or products with high requirements for surface quality; Wooden box packaging: For high – precision or special – specification angle steel, wooden box packaging is used to ensure that the products are not damaged during transportation and handling. |

| Delivery Time | 3 – 7 days for regular specification orders; 7 – 15 days for customized specification orders. |

| Payment Terms | T/T (Telegraphic Transfer), L/C (Letter of Credit), etc., negotiable. |

| After – sales Service | Provide technical consultation. In case of product quality problems, negotiate return, replacement, or replenishment. |

Physical properties and chemical properties:

Physical properties

Appearance:

Usually long strips, with a right triangle cross section, two perpendicular sides, and a generally smooth surface, but there may be some traces left during the rolling process, and the color is mostly silver-gray.

Density:

The density of carbon steel angle is about 7.85g/cm³, which makes it much heavier than some metals with lower density such as aluminum at the same volume.

Melting point:

The melting point of general carbon steel is around 1450-1500℃, and the specific value will vary slightly depending on the content of carbon and other impurity elements in carbon steel.

Electrical conductivity and thermal conductivity:

It has good electrical conductivity and thermal conductivity, and can conduct current and heat well, but its electrical and thermal conductivity are not as good as metals such as copper and aluminum.

Magnetic properties:

At room temperature, carbon steel angles are usually ferromagnetic and can be attracted by magnets.

Chemical properties

Corrosion resistance:

Carbon steel angles easily react with oxygen, water, etc. in the air to rust, and its main component, iron, will be oxidized into iron oxide. In a humid environment, the rusting speed will accelerate. If it is in an environment containing corrosive media such as acids, alkalis, and salts, the corrosion rate of carbon steel angles will increase significantly.

Oxidation:

At high temperatures or in a specific oxidizing atmosphere, the iron element on the surface of carbon steel angles is easily oxidized to form iron oxides of different valence states. For example, when heated to a certain temperature in air, black ferroferric oxide or red ferric oxide will be generated.

Reaction with acids:

Carbon steel angles can react chemically with a variety of acids. For example, reaction with hydrochloric acid will generate ferrous chloride and hydrogen, and reaction with sulfuric acid will generate ferrous sulfate and hydrogen. If the acid concentration is high or the reaction conditions are more intense, the reaction rate will be accelerated, and some other side reactions may be accompanied.

Reaction with alkali:

Under normal circumstances, the reaction of carbon steel angles with alkali is relatively slow. However, under some special conditions, such as high temperature, concentrated alkali solution, etc., some components in carbon steel may react with alkali, but this reaction is relatively less common.

Weldability:

Carbon steel angle steel has good weldability. During the welding process, the steel is heated to the melting point and fuses with the welding rod or wire to form a strong welded joint. However, it is necessary to pay attention to controlling the welding parameters during the welding process to avoid welding defects such as pores and cracks. At the same time, appropriate heat treatment may be required after welding to improve the performance of the welded joint.

Application:

Carbon steel angles are widely used in many fields. In the construction industry, it is a key material for building house frames, steel structure factories and bridges. It can withstand large loads and ensure structural stability. It is also commonly used to make decorative components such as door and window frames and stair handrails. In the field of mechanical manufacturing, it can be used as equipment brackets and mechanical frames to provide stable support for various types of machinery. In power engineering, carbon steel angles are used to construct transmission towers and substation structures to ensure the safe operation of power facilities. In addition, it is also used to manufacture daily necessities such as hardware shelves, fences, ladders, etc. It also plays an important role in scenes such as shipbuilding and agricultural greenhouse construction. With its good mechanical properties and economy, it has become a common material in industrial and civil fields.