PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

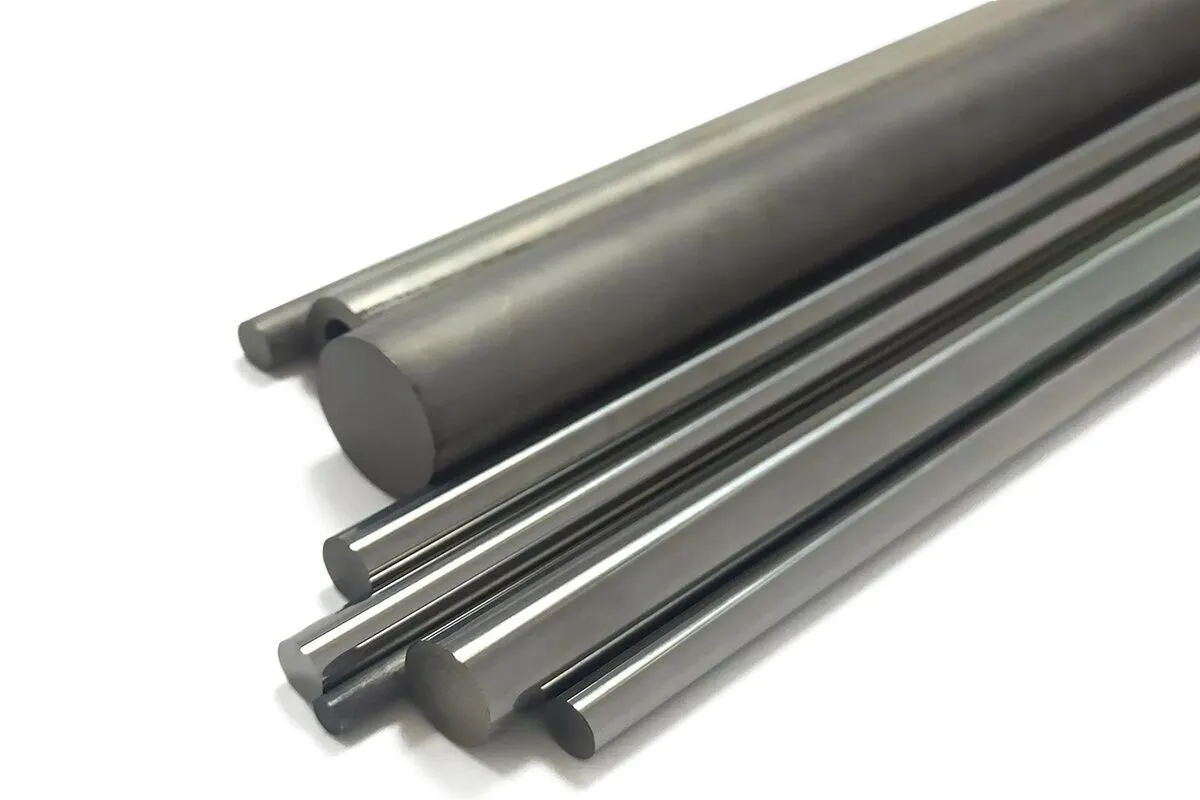

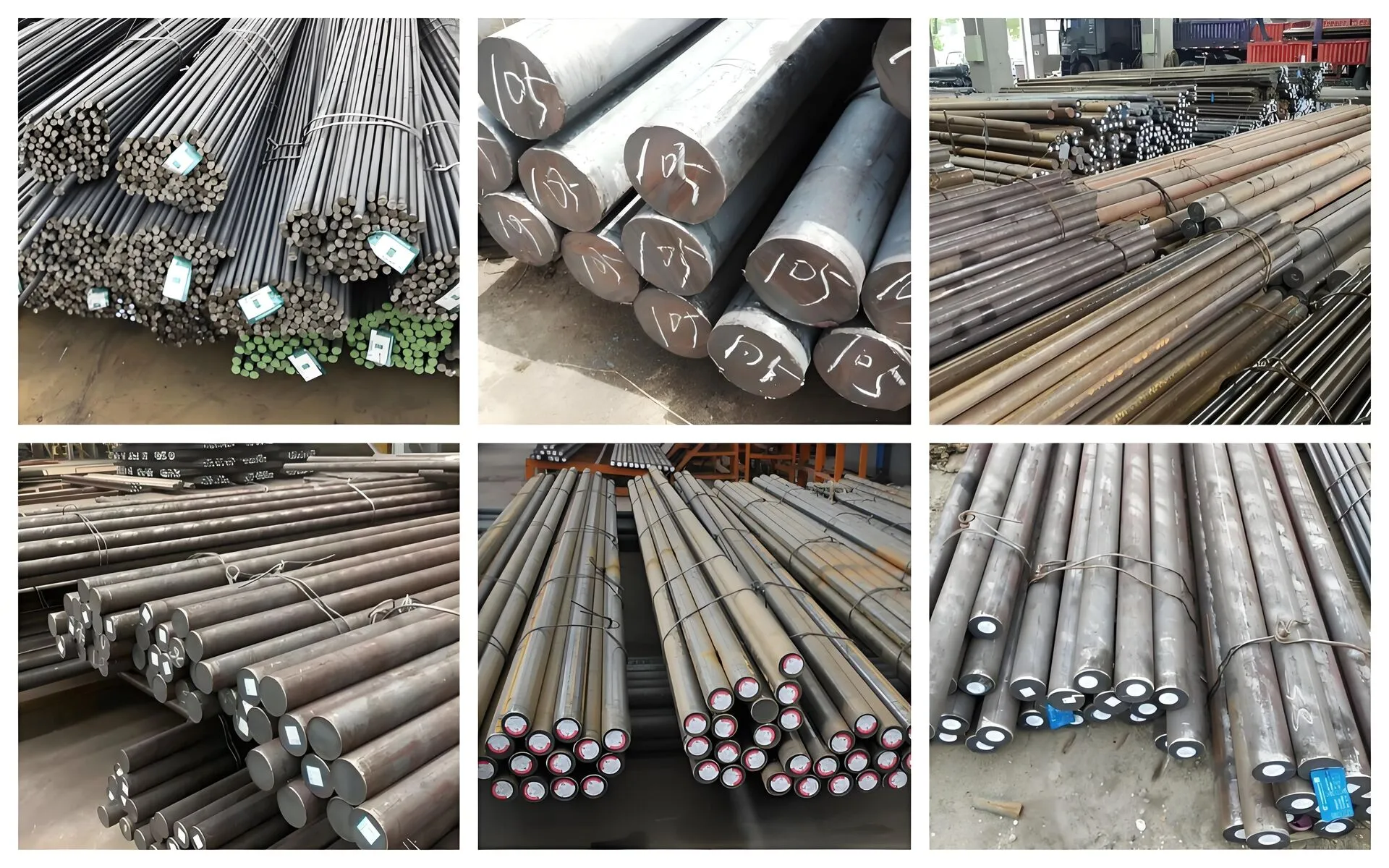

Carbon steel bar

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product Details Table:

| Category | Details |

|---|---|

| Strength | Medium and high – carbon steel bars can withstand heavy loads. The tensile strength of grade 1045 bars is approximately 600MPa. |

| Toughness | Low – carbon steel bars have excellent impact resistance, reducing the risk of brittle fracture. |

| Machinability | Easy to machine through operations like turning, drilling, and welding, meeting diverse manufacturing needs. |

| Hardness | The hardness of high – carbon steel bars can be significantly increased through heat treatment, enhancing wear resistance. |

| Surface Treatment | Black skin (hot – rolled original surface) Bright annealing to enhance corrosion resistance and luster Polishing for a mirror – like effect Galvanizing and nickel – plating for superior anti – corrosion Painting for additional protection and decoration |

| Application Fields | Machinery Manufacturing: Used for parts such as shafts, gears, bolts, and nuts. Construction: Applied to structural components, scaffolding, and formwork. Automotive Industry: Used for components like half – shafts, steering knuckles, and tie rods. Hardware Tools: Suitable for wrenches, screwdrivers, and other tools. Furniture Manufacturing: Used to construct sturdy frames and connectors. |

| Quality Assurance | Strict quality control at all production stages Provide material certificates and quality inspection reports Support third – party inspection to ensure product quality |

| Packaging Methods | Plastic film winding Woven bag packaging Wooden box packaging Customized packaging solutions are available |

| Pricing and Ordering | Price: Varies depending on materials, specifications, and market conditions. Contact our sales team for a detailed quote. Delivery Time: 3 – 7 days for standard orders; 10 – 20 days for customized orders. Payment Methods: T/T, L/C, and other negotiable methods |

Physical and chemical properties:

Physical properties

Appearance:

Usually presents a metallic luster, the color is mostly silver gray to dark gray, the specific color may vary depending on the surface treatment method and the degree of oxidation.

Density:

The density of carbon steel is generally between 7.8 – 7.85g/cm³, which varies slightly with the change of carbon content and other alloying elements.

Hardness:

The hardness of carbon steel bars is closely related to the carbon content. Low carbon steel has a lower hardness, and the Brinell hardness is usually between 100 – 150HB; medium carbon steel has a moderate hardness of about 150 – 250HB; high carbon steel has a higher hardness, which can reach 250 – 600HB or even higher, and the hardness will be further increased after heat treatment such as quenching.

Strength:

The yield strength of low carbon steel is generally around 200-300MPa, and the tensile strength is around 300-400MPa; the yield strength of medium carbon steel can reach 300-450MPa, and the tensile strength is around 450-650MPa; the strength of high carbon steel is higher, and the tensile strength can exceed 700MPa.

Toughness:

Low carbon steel has good toughness, its impact toughness value is high, and it can withstand large deformation without breaking; medium carbon steel has moderate toughness; high carbon steel has relatively low toughness, but its strength and hardness are high.

Electrical conductivity and thermal conductivity: Carbon steel has good electrical conductivity and thermal conductivity, and can conduct current and heat well. Its electrical and thermal conductivity is slightly lower than pure iron, but better than many other alloy materials.

Magnetism:

Carbon steel is usually ferromagnetic at room temperature and can be attracted by magnets, but its magnetism may change at high temperatures or after certain special treatments.

Chemical properties

Corrosion resistance:

Carbon steel easily rusts due to chemical reactions with oxygen, water, etc. in the air, and its main component is iron oxide. In a humid environment, the rusting speed will be accelerated. In addition, carbon steel has poor corrosion resistance to chemicals such as acids, alkalis, and salts, and is easily corroded. For example, carbon steel will quickly dissolve in strong acids such as dilute sulfuric acid and hydrochloric acid to produce hydrogen.

Oxidizability:

Carbon steel is easily oxidized under heating or in the presence of oxidants. For example, at high temperatures, carbon steel reacts with oxygen to produce iron oxide.

Weldability:

Carbon steel has good weldability and can be connected together by welding. However, as the carbon content increases, the welding performance will decrease. Special welding processes and measures are required when welding high carbon steel to prevent defects such as welding cracks.

Heat treatment performance: Carbon steel can significantly change its organizational structure and properties through different heat treatment processes, such as quenching, tempering, normalizing, annealing, etc. For example, quenching can increase the hardness and strength of carbon steel, but will reduce its toughness; tempering can restore toughness to a certain extent while maintaining high hardness and strength.

Application:

Carbon steel plates are widely used. In the construction field, they are used to build structures such as factories and bridges. With high strength and good toughness, they ensure the stability of the buildings. In the machinery manufacturing industry, they can be processed into various parts, such as machine tool beds and boxes, to provide basic support for equipment operation. In the automotive industry, carbon steel plates are used to manufacture car bodies, chassis, etc., and they meet complex modeling requirements through stamping, while taking into account strength and cost. In addition, in terms of container manufacturing, storage tanks, reactors, etc. can be made, which are suitable for storing and processing various liquids and gases; they are also used in the production of hardware products, such as making daily tools, door and window frames, etc., and have become the basic materials for many industries due to their economy and practicality.