PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

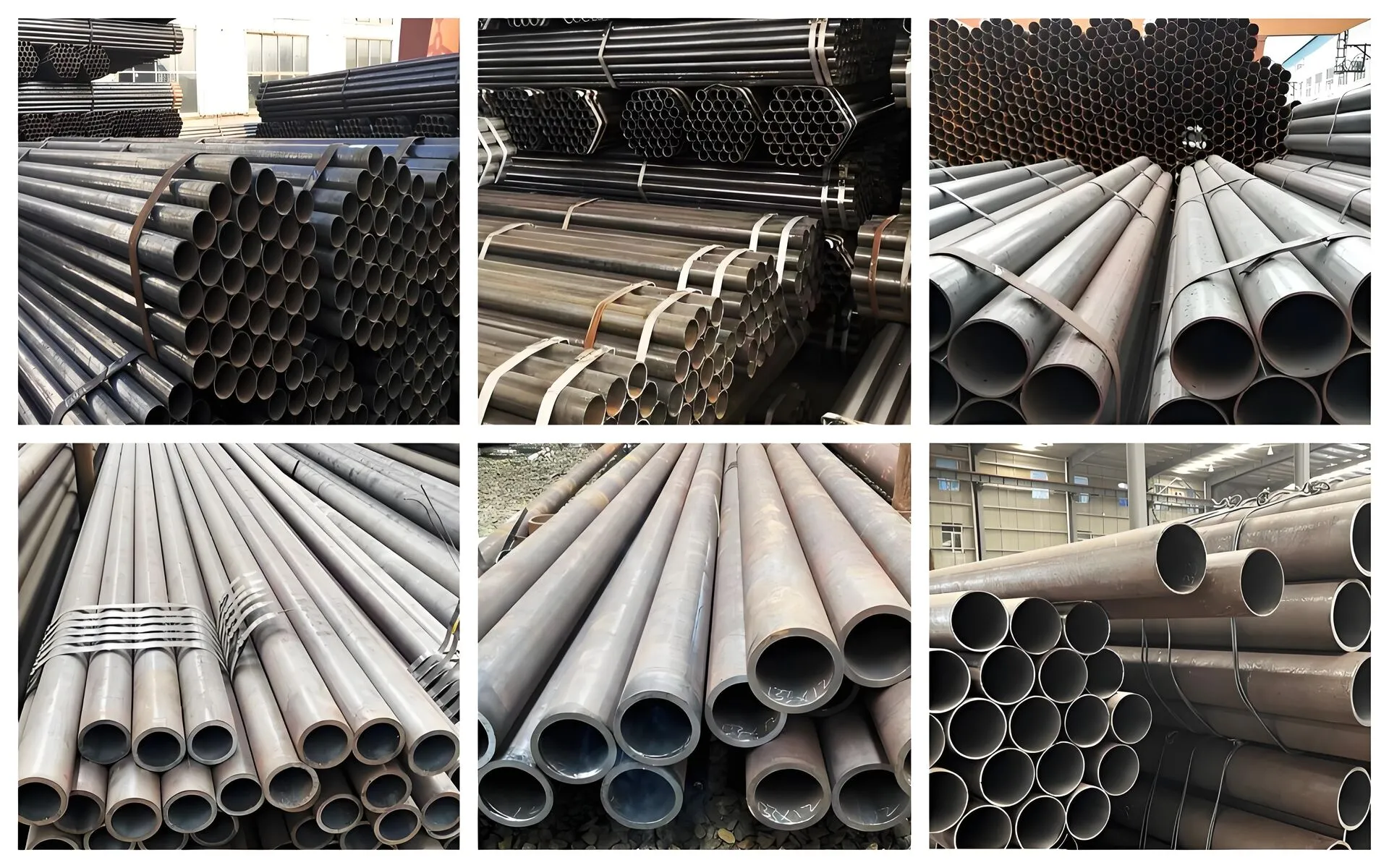

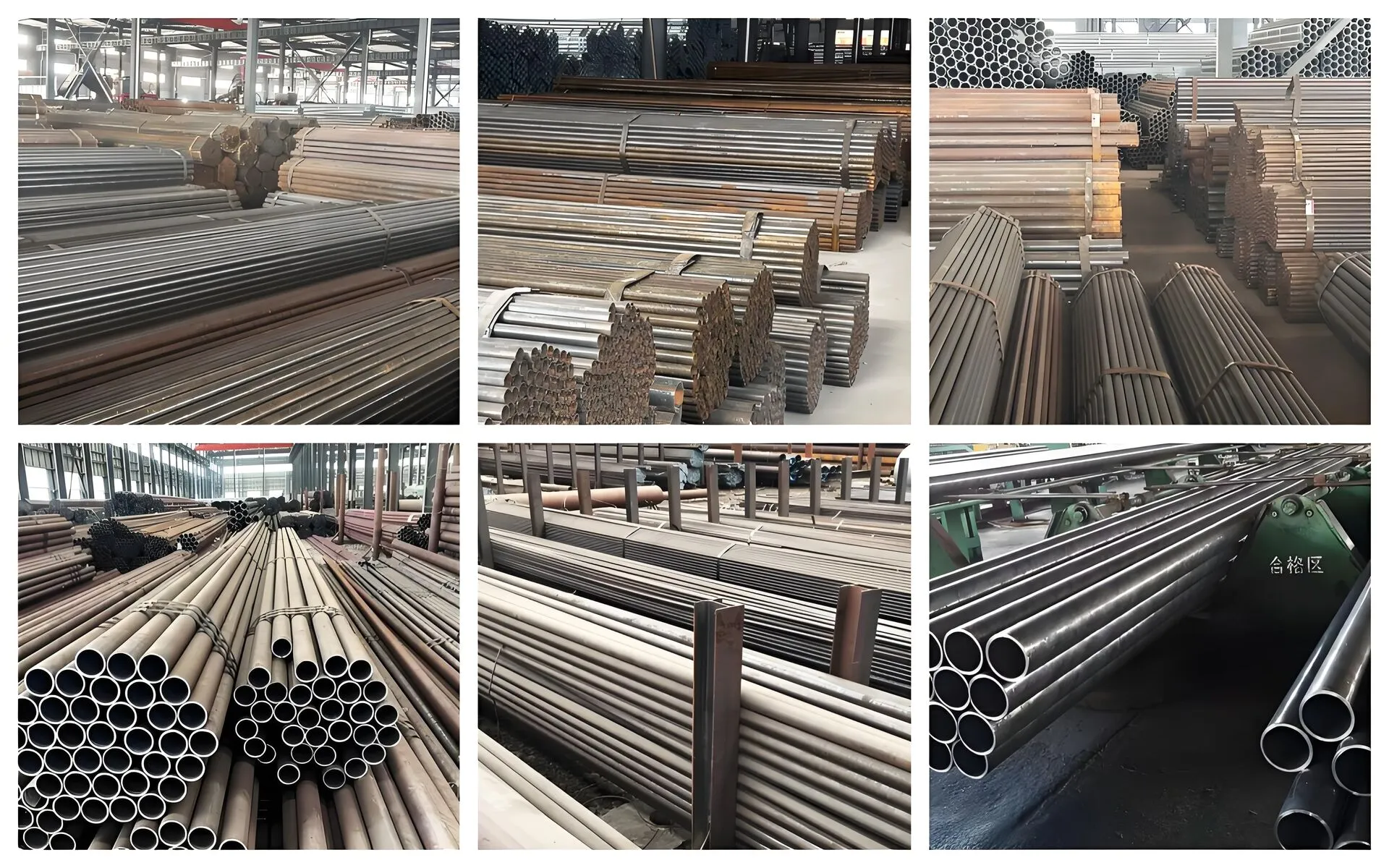

Carbon steel pipe

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details table:

| Items | Details |

|---|---|

| Strength | High tensile strength and yield strength, capable of withstanding high pressure and tension |

| Toughness | Good toughness, adaptable to different working conditions |

| Machinability | Easy to cut, weld, bend and other processing operations |

| Corrosion Resistance | Has certain corrosion resistance in general environments, which can be enhanced by galvanizing and other treatments |

| Surface Treatment | Galvanizing, painting, epoxy coating, PE coating, etc., meeting the needs of different usage scenarios |

| Application Scope | Oil and gas transportation, building water supply and drainage, machinery manufacturing, power engineering, bridge construction, chemical pipelines, etc. |

| Standards | ASTM A53, API 5L, GB/T 3091, GB/T 8163, etc. |

| Connection Methods | Welding, flange connection, threaded connection |

| Packaging | Bundling, woven bag packaging, wooden box packaging, etc. to prevent damage during transportation |

| Quality Grade | Meets relevant standard requirements, third – party inspection supported |

| Price | Fluctuates according to material, specifications, and market conditions. For details, please consult. |

| Delivery Time | 7 – 15 days for regular orders, subject to negotiation for customized orders |

| Payment Terms | T/T, L/C, etc. |

| After – sales Service | Provide technical support, and quality issues can be negotiated for resolution |

| Single gross weight | 2.000 kg |

Physical and chemical properties:

Physical properties

Density:

The density of carbon steel pipes is generally between 7.85 – 7.98g/cm³, which may vary slightly due to different carbon content and other trace elements. For example, the density of ordinary Q235 carbon steel pipes is about 7.85g/cm³, while the density of steels with higher carbon content may be slightly higher.

Melting point:

Usually around 1420 – 1540℃. Carbon steels with lower carbon content have relatively higher melting points, such as Q195 carbon steel, which has a melting point of about 1530 – 1540℃; as the carbon content increases, the melting point will decrease, such as the melting point of high carbon steel may be 1420 – 1450℃.

Coefficient of thermal expansion:

In the temperature range from room temperature to 100℃, the thermal expansion coefficient of carbon steel pipes is about 1.2 – 1.3×10⁻⁵/℃. This means that when the temperature changes, the length of the carbon steel pipe will change to a certain extent.

Thermal conductivity:

Carbon steel pipe has good thermal conductivity, and its thermal conductivity is about 40 – 50W/(m・K). Compared with some non-ferrous metals, such as copper and aluminum, carbon steel has poor thermal conductivity, but it is still at a medium level among metal materials and can meet the thermal conductivity requirements in many engineering applications.

Electrical conductivity:

Carbon steel pipe has a certain electrical conductivity, but it is not as good as metals such as copper and aluminum. Its electrical conductivity is generally around 1.5 – 2.0×10⁷ S/m. With the increase of carbon content and the presence of impurities, the electrical conductivity will decrease.

Chemical properties

Corrosion resistance:

In the atmospheric environment, carbon steel pipes easily react with oxygen and moisture in the air to generate rust (the main component is ferric oxide). In some specific chemical environments, such as acidic, alkaline or salt solutions, carbon steel pipes have poor corrosion resistance. For example, in a dilute sulfuric acid solution, carbon steel pipes will undergo a chemical reaction, and iron reacts with sulfuric acid to generate ferrous sulfate and hydrogen. However, the corrosion resistance of carbon steel pipes can be improved through some surface treatment methods, such as galvanizing, painting, nickel plating, etc.

Oxidation:

Carbon steel pipes are easily oxidized at high temperatures and react with oxygen to form metal oxides. For example, when heated to 500-600℃, a layer of oxide scale will form on the surface of carbon steel pipes, the main components of which are ferroferric oxide and ferric oxide.

Stability:

At room temperature and pressure, carbon steel pipes are relatively stable in most cases. However, under high temperature, high pressure or strong chemical corrosion environment, its chemical stability will be affected, and chemical reactions may occur, resulting in a decrease in material performance.

Application:

Carbon steel pipes are widely used in many fields due to their high strength, good processability and economy. In the construction field, it is used to build scaffolding and steel structure frames to provide stable support for buildings; in the water supply and drainage system, carbon steel pipes transport tap water and sewage to ensure efficient transmission of fluids. In the machinery manufacturing industry, carbon steel pipes are processed into mechanical parts, such as hydraulic pipes, transmission shafts, etc., to meet the needs of mechanical operation. In the energy industry, it is a key material for oil and natural gas pipelines, which can withstand high pressure and ensure long-distance and stable energy transportation; in thermal power plants, carbon steel pipes are used to manufacture steam pipes to transmit high-temperature and high-pressure steam. In the chemical industry, carbon steel pipes can be used to transport various chemical raw materials and products with relatively weak corrosiveness.