PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Color-coated tile

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details table:

| Items | Details |

|---|---|

| Product Name | Color – Coated Tile |

| Place of Origin | Jiangsu, China |

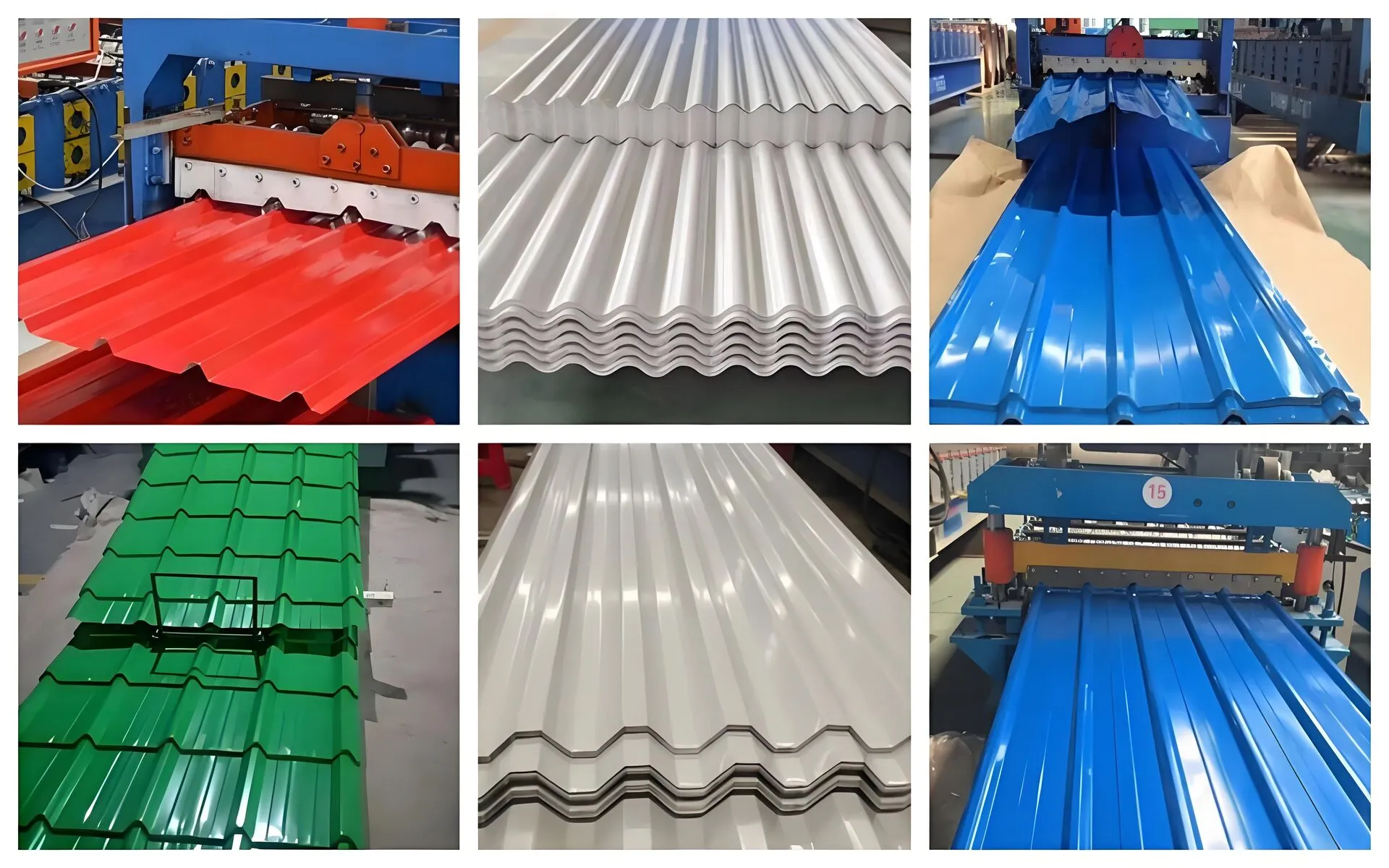

| Production Process | Using hot – dip galvanized sheets, hot – dip aluminum – zinc sheets, etc. as the base materials. After pretreatment processes such as degreasing and chemical conversion to enhance the adhesion of the coating, organic coatings (such as polyester, fluorocarbon, etc.) are applied by roll coating or spraying. Finally, it is cured by high – temperature baking and then formed into specific tile shapes through pressing. |

| Execution Standards | Comply with standards such as GB/T 12754 – 2019 Colored Coated Steel Sheets and Strips and GB 50205 – 2020 Code for Acceptance of Construction Quality of Steel Structures, etc. |

| Base Materials | Hot – dip galvanized steel sheets (zinc coating content: 60 – 275g/㎡), hot – dip aluminum – zinc steel sheets (aluminum – zinc coating content: 100 – 150g/㎡) |

| Coating Types | Polyester (PE): Rich in colors, low in cost, suitable for general buildings; Silicone – Modified Polyester (SMP): Better weather resistance and abrasion resistance than PE; High – Durability Polyester (HDP): Strong UV resistance; Polyvinylidene Fluoride (PVDF): Excellent weather resistance and chemical corrosion resistance, suitable for high – end buildings |

| Coating Structures | 2/1 (two – coat on the upper surface, one – coat on the lower surface, one – bake); 2/2 (two – coat on the upper surface, two – coat on the lower surface, two – bake) |

| Thickness | 0.3mm – 1.2mm |

| Effective Width | 820mm, 900mm, 980mm, etc. (customizable) |

| Length | Customized according to requirements (conventional: 3m – 12m) |

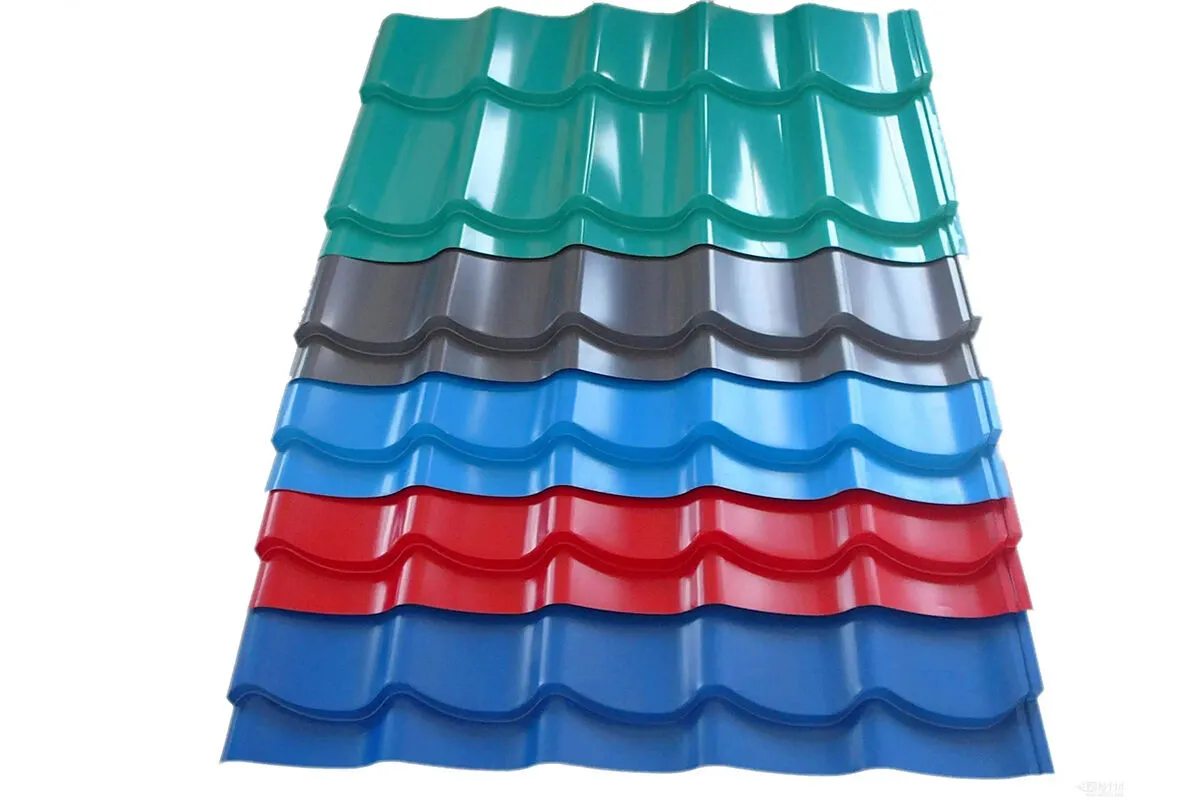

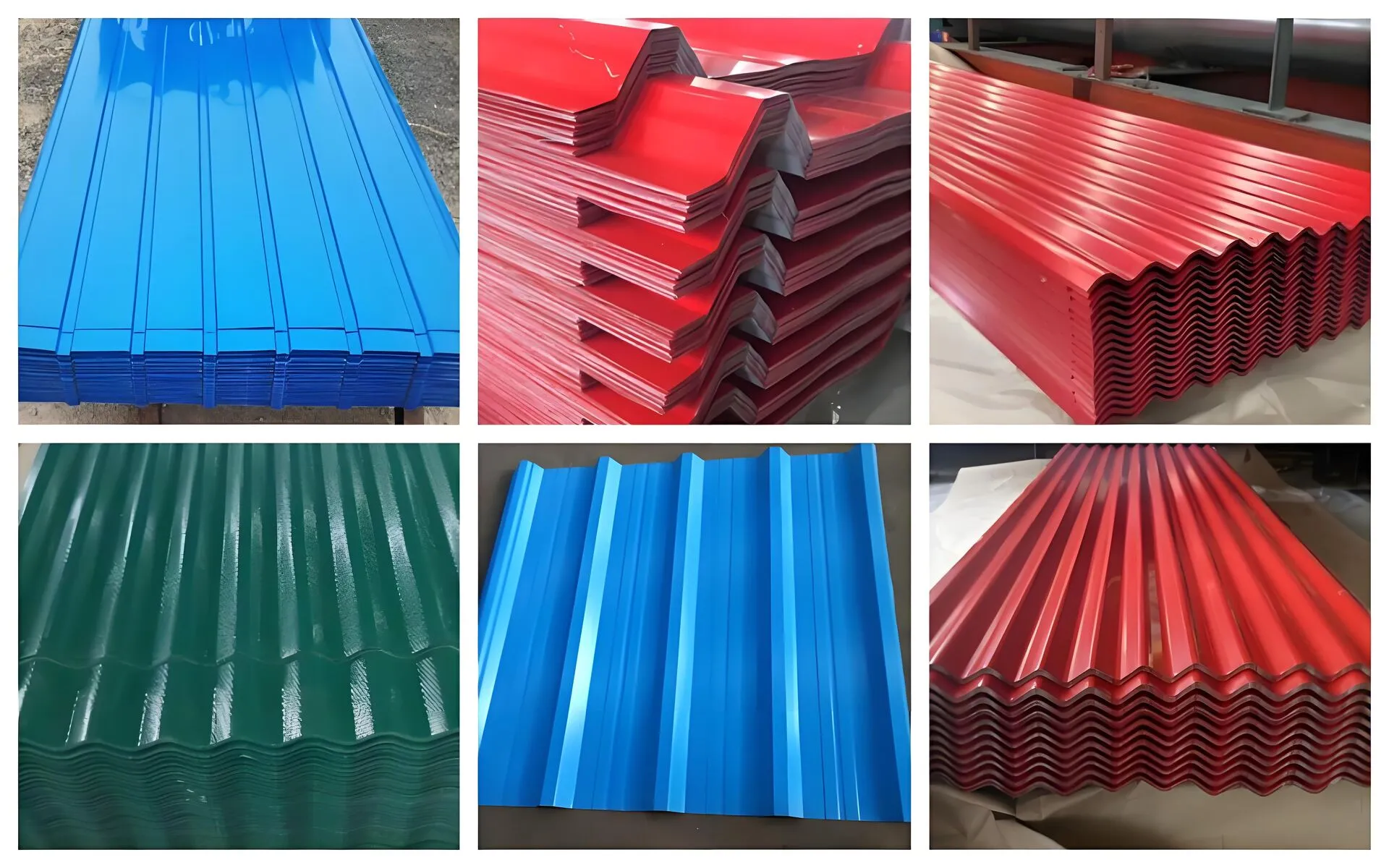

| Tile Types | Wave – type, Trapezoid – type, Angle – chase – type, Glazed – type, etc., more than ten types (selectable as needed) |

| Colors | Conventional colors such as ocean blue, scarlet, ivory white, etc. Customization according to the Pantone color card is supported. |

| Corrosion Resistance | Double protection from the zinc layer of the base material and the coating, with a service life of up to 10 – 30 years in ordinary environments |

| Waterproofness | Unique tile shape design combined with the lap joint structure effectively blocks rainwater penetration |

| Weather Resistance | Resistant to UV rays and aging, adaptable to various climates such as high temperature, severe cold, and acid rain |

| Decorativeness | Long – lasting and bright colors, and the combination of various tile types and colors enhances the aesthetic appeal of buildings |

| Lightweight | The weight per unit area is about 1/3 – 1/5 of that of traditional tiles, reducing the load – bearing of buildings |

| Easy Installation | Fixed with self – tapping screws, with high installation efficiency and low construction cost |

| Industrial Buildings | Roofs and walls of factories, warehouses, workshops, etc. |

| Civil Buildings | Roof decoration of villas, residences, and new rural construction |

| Public Buildings | Roofs and exterior walls of schools, hospitals, stadiums, etc. |

| Temporary Buildings | Prefabricated houses, temporary sheds, farmers’ markets, etc. |

| Quality Assurance | Provide material reports and coating performance inspection reports, and support third – party inspection |

| Packaging Method | Wrapped with plastic film and bundled with steel strips, with wooden pallets at the bottom to prevent scratches and deformation during transportation |

| Delivery Time | 3 – 7 days for regular orders; 7 – 15 days for customized orders |

| Payment Terms | T/T (Telegraphic Transfer), L/C (Letter of Credit), negotiable |

| After – sales Service | Provide installation guidance. In case of quality problems, negotiate returns and exchanges |

Physical properties and chemical properties:

Physical properties

Appearance:

It has a regular corrugated shape or other specific shapes, with bright and uniform surface colors and good gloss. A variety of color options can be provided according to design requirements to meet the decorative requirements of different architectural styles.

Density:

Similar to color-coated coils, it mainly depends on the substrate and coating materials used, generally around 7.8-7.9g/cm³. Due to the hollow or undulating structure of the shape of the tile, the weight of the color-coated tile of the same area is slightly lighter than that of the color-coated flat plate.

Hardness:

The surface hardness of the color-coated tile is relatively high, which can resist a certain degree of external impact and friction, and is not easy to have obvious pits or scratches. This helps to maintain the integrity and appearance quality of the tile during installation and use.

Flexibility:

Although the color-coated tile has a certain rigidity after being pressed, it still has a certain flexibility and can be bent within a certain range without breaking. This flexibility enables it to adapt to slight deformations of some building structures and slight collisions during transportation and installation.

Thermal performance:

It has a certain thermal insulation performance and can slow down the transfer of heat to a certain extent. Different combinations of coatings and substrates will affect their thermal conductivity. For example, some color-coated tiles with heat-insulating coatings or special substrates have better heat-insulating effects, which help reduce the energy consumption of buildings.

Chemical properties

Corrosion resistance:

The substrate of color-coated tiles is usually treated with anti-corrosion treatments such as galvanizing and galvanizing. The coating isolates the substrate from the external environment, effectively preventing the erosion of the substrate by air, moisture, acid and alkali, and has good corrosion resistance. In normal outdoor environments, it can be used for a long time without serious rust.

Weather resistance:

The coating has excellent weather resistance and can resist the long-term effects of natural factors such as ultraviolet rays, rain, wind and sand, and is not prone to fading, powdering, cracking, etc. After years of outdoor exposure, high-quality color-coated tiles can still maintain good color and performance, reducing the cost and trouble caused by frequent maintenance.

Chemical stability:

Under normal use conditions, the coating of color-coated tiles is chemically stable and not easy to react with common chemicals. However, long-term exposure to high concentrations of strong acids, strong alkalis or other corrosive chemicals may destroy the protective effect of the coating and cause corrosion of the substrate.

Flammability:

Similar to color-coated coils, the flammability of color-coated tiles depends on the type of coating. Color-coated tiles with ordinary polyester coatings are flame-retardant materials. They will burn to a certain extent when exposed to open flames, but the burning speed is relatively slow and they usually extinguish themselves after leaving the fire source. Some color-coated tiles that have undergone special fireproofing treatments have better flame retardant properties, which can delay the spread of fire when a fire occurs and improve the fire safety performance of buildings.

Application:

Color – coated tile is widely used in the construction industry. It is commonly employed for roofing in residential, commercial, and industrial buildings, providing both protection from the elements and an aesthetically pleasing appearance. Its waterproof and corrosion – resistant properties ensure the durability of the roof. In addition, it can be used for exterior wall decoration, adding color and texture to the building facade. It is also suitable for the construction of sheds, warehouses, and garages. Moreover, due to its light weight and easy installation, it is a popular choice for renovation projects, helping to quickly upgrade the look and performance of buildings.