PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

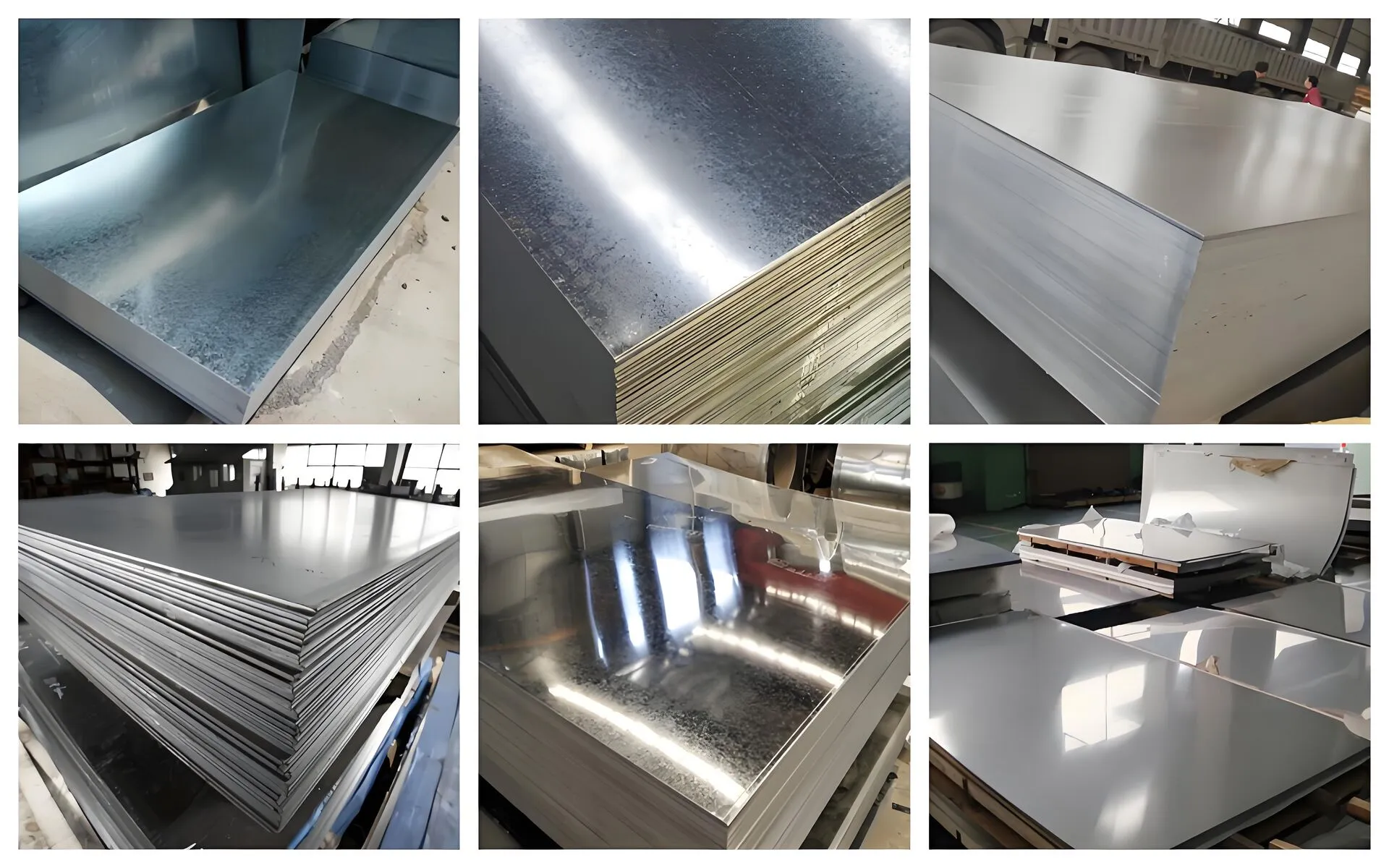

Galvanized sheet

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details:

| Items | Details |

|---|---|

| Product Name | Galvanized Sheet |

| Base Material | High – quality low – carbon steel, such as DC01, SPCC, etc. |

| Galvanizing Types | Hot – dip galvanized sheet (GI sheet): Thick zinc layer, with strong corrosion resistance; Electrogalvanized sheet (EG sheet): Smooth surface, suitable for painting. |

| Zinc Coating Weight | Hot – dip galvanizing: 60 – 600g/㎡; Electrogalvanizing: 8 – 40g/㎡ |

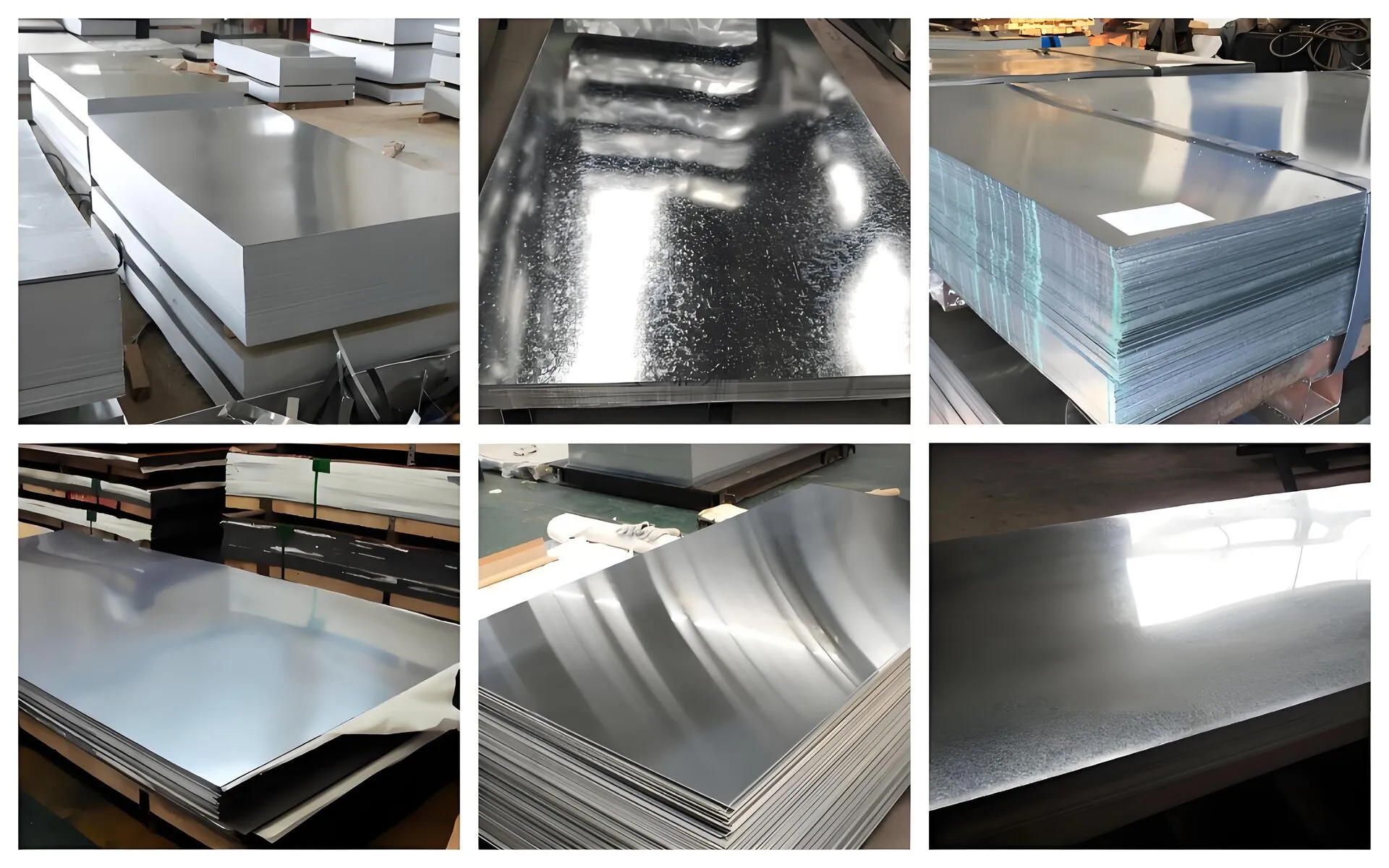

| Thickness | 0.15mm – 4.0mm |

| Width | 600mm – 1500mm |

| Length | 1000mm – 6000mm |

| Surface Treatment | Passivation, oil coating, anti – fingerprint treatment, etc., to enhance anti – rust and processing performance. |

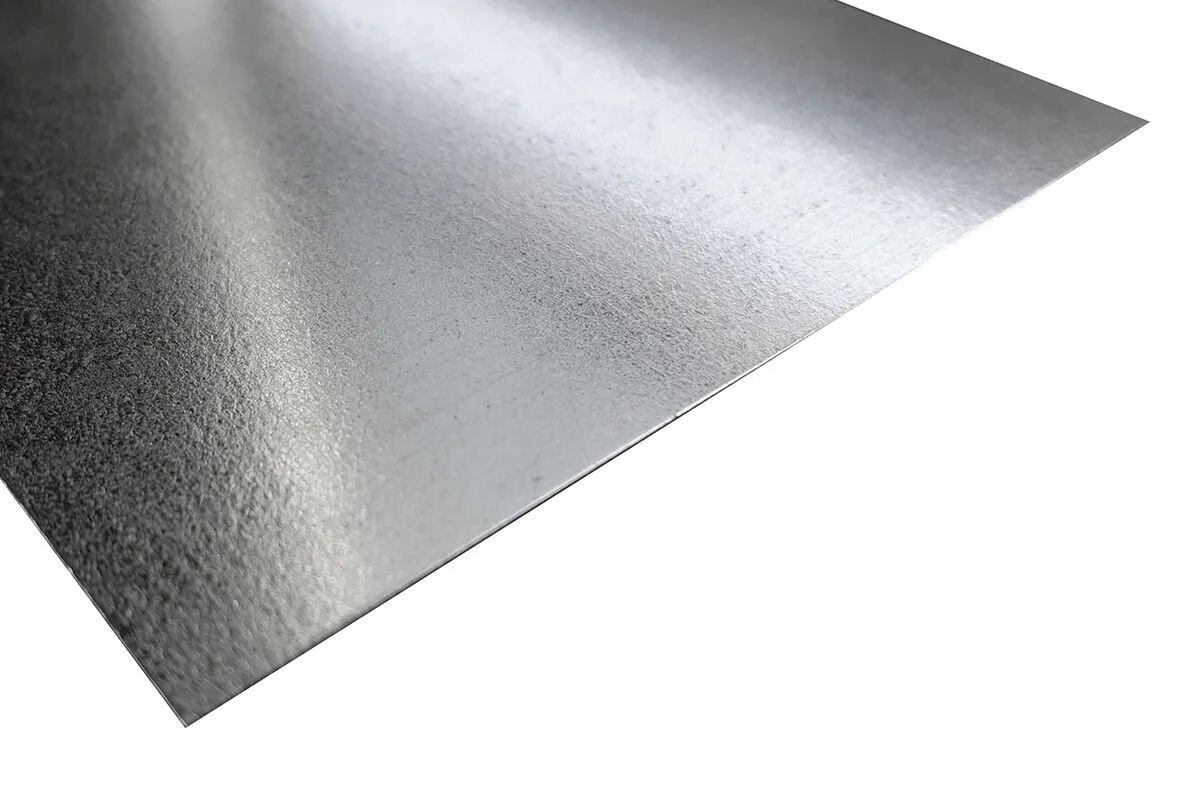

| Surface Appearance | Normal spangle, minimized spangle, spangle – free |

| Corrosion Resistance | The zinc layer effectively protects the steel sheet, and the service life of hot – dip galvanized sheets can reach 10 – 30 years. |

| Workability | Excellent bending, stamping, and welding properties, meeting various processing requirements. |

| Appearance Quality | Smooth surface, uniform color, with no obvious defects. |

| Construction Industry | Used for roofing, wall cladding, keels, ventilation ducts, etc. |

| Home Appliance Manufacturing | Shells and internal structural components of refrigerators, air conditioners, washing machines, etc. |

| Automotive Industry | Vehicle bodies, chassis, components, etc. |

| Furniture Manufacturing | Table and chair frames, cabinet bodies, etc. |

| Others | Billboards, cable trays, hardware products, etc. |

| Quality Assurance | Provide material certificates, zinc coating weight inspection reports, and support third – party inspection. |

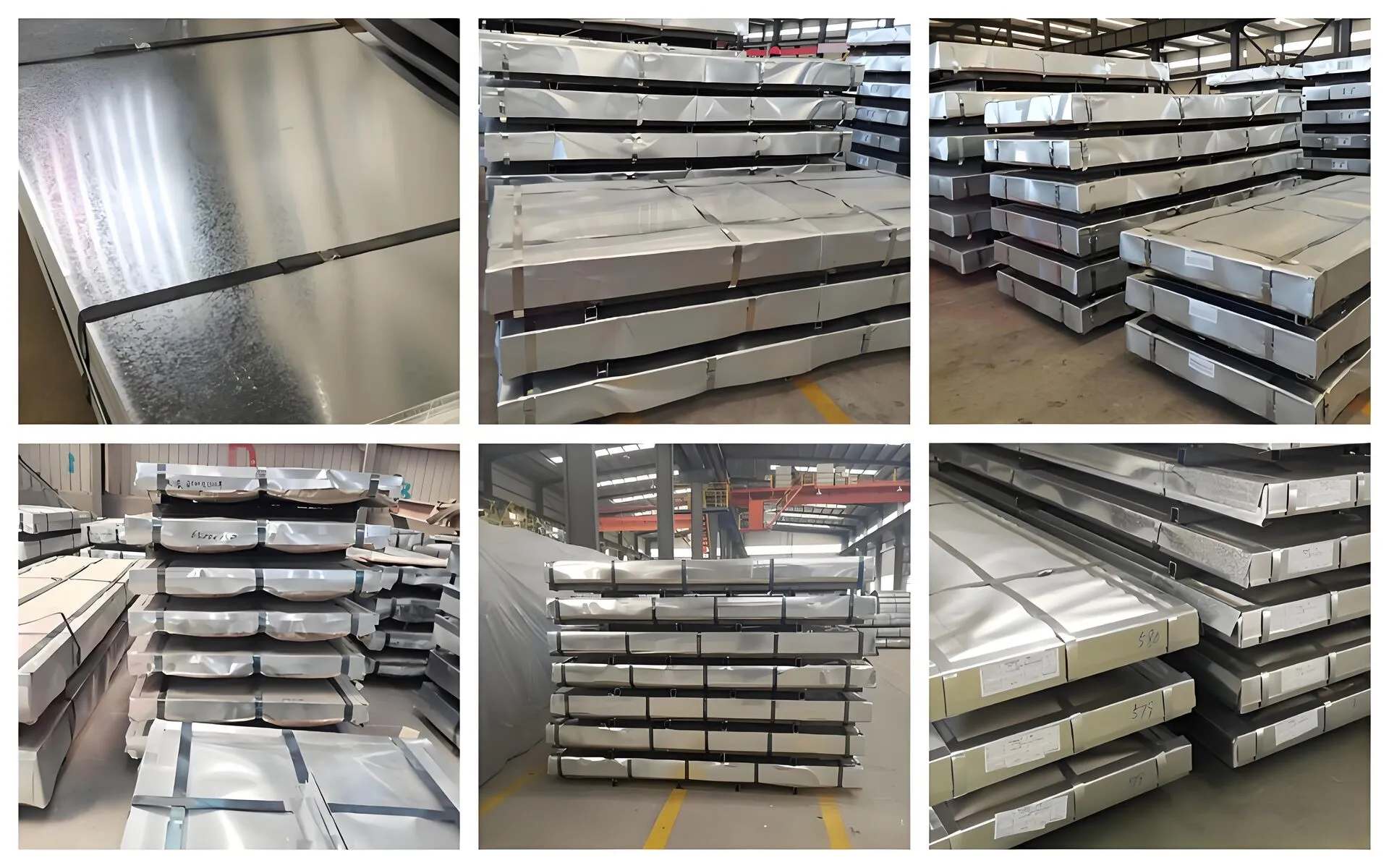

| Packaging Method | Moisture – proof paper + steel strip bundling, or wooden box packaging to prevent scratches and moisture during transportation. |

| Delivery Time | 3 – 7 days for regular orders; 10 – 20 days for customized orders. |

| Payment Terms | T/T (Telegraphic Transfer), L/C (Letter of Credit), etc., negotiable. |

| After – sales Service | Provide technical support. In case of quality problems, negotiate returns and exchanges. |

Physical properties and chemical properties:

Physical properties

Appearance:

Usually presents a silver-grey metallic luster and a relatively smooth surface. The zinc layer of hot-dip galvanized sheet may have a zinc flower pattern, while the surface of electro-galvanized sheet is smoother and more delicate.

Density:

Since it is galvanized on the surface of the steel sheet, its density is between steel and zinc, generally about 7.85 – 7.2g/cm³, and the specific value depends on the thickness of the zinc layer and the type of steel.

Hardness:

The hardness of galvanized sheet is higher than that of pure zinc and slightly higher than that of ordinary steel sheet. This is because the zinc layer improves the strength and wear resistance of the sheet surface to a certain extent, and its hardness is generally between HV100 – 200 (Vickers hardness).

Ductility:

It has good ductility and can withstand a certain degree of deformation such as bending and stretching without breaking. This allows the galvanized sheet to be made into products of various shapes during processing, such as bending into pipes, stamping into parts, etc.

Electrical conductivity and thermal conductivity: Galvanized sheet has good electrical conductivity and thermal conductivity, which is similar to ordinary steel. This enables it to meet the requirements in some application scenarios that require electrical or thermal conductivity, such as the housing of electrical equipment, heat dissipation components, etc.

Chemical properties

Corrosion resistance:

This is the most important chemical property of galvanized sheet. Zinc easily reacts with oxygen in the air to form a dense zinc oxide film on the surface, which can prevent the internal steel from contacting with air, water, etc., thereby playing a protective role. In a general atmospheric environment, galvanized sheet can be used for a long time without obvious rust.

Chemical stability:

At room temperature, galvanized sheet has a certain resistance to most chemicals such as acids, alkalis, and salts. However, in some specific highly corrosive environments, such as high concentrations of sulfuric acid and hydrochloric acid, the zinc layer will gradually be corroded. When the zinc layer is completely destroyed, the internal steel will also begin to corrode.

Weldability:

Galvanized sheet has good weldability. During the welding process, the zinc layer will undergo some chemical reactions at high temperatures, but it will not have much impact on the welding quality. However, in order to ensure the welding effect, some special treatments are usually required on the welding parts of the galvanized sheet before welding, such as removing the zinc layer, applying flux, etc.

Surface activity:

The surface of the galvanized sheet has a certain activity and is easy to react chemically with some organic coatings, adhesives, etc. to form a good combination. Therefore, the galvanized sheet can obtain better coating adhesion during the surface treatment process such as painting and spraying, thereby further improving its corrosion resistance and decorative properties.

Application:

Galvanized sheet is widely used in many fields due to its excellent corrosion resistance and economy. In the construction industry, it is used to build roofs, walls and keels to resist wind and rain erosion and extend the service life of the building. In the field of home appliance manufacturing, it is often used as the outer shell material of refrigerators, air conditioners, etc., which not only ensures beautiful appearance but also prevents rust damage. The automotive industry uses it to manufacture body parts, reducing weight while enhancing rust resistance. In addition, it is also used to manufacture billboards, ventilation ducts, cable trays, etc. In furniture production, it can also be used to make table and chair frames and cabinets. With good processing performance, it can meet diverse modeling needs and is an indispensable material for modern industry and daily life.