PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Stainless steel pipe

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details table:ipe

| Product Name | Stainless Steel Pipe |

|---|---|

| Material Type | Stainless steel (square tubes, rectangular tubes, round tubes) |

| Product Types | Square tubes, rectangular tubes, round tubes |

| Thickness | 0.5-75mm (general); 0.16mm-4.0mm (for square/rectangular/round tubes of specified specifications) |

| Specifications | – Round tubes: Outer diameter 8mm-680mm – Square tubes: 10x10mm-300x300mm – Rectangular tubes: 10x20mm-120x180mm |

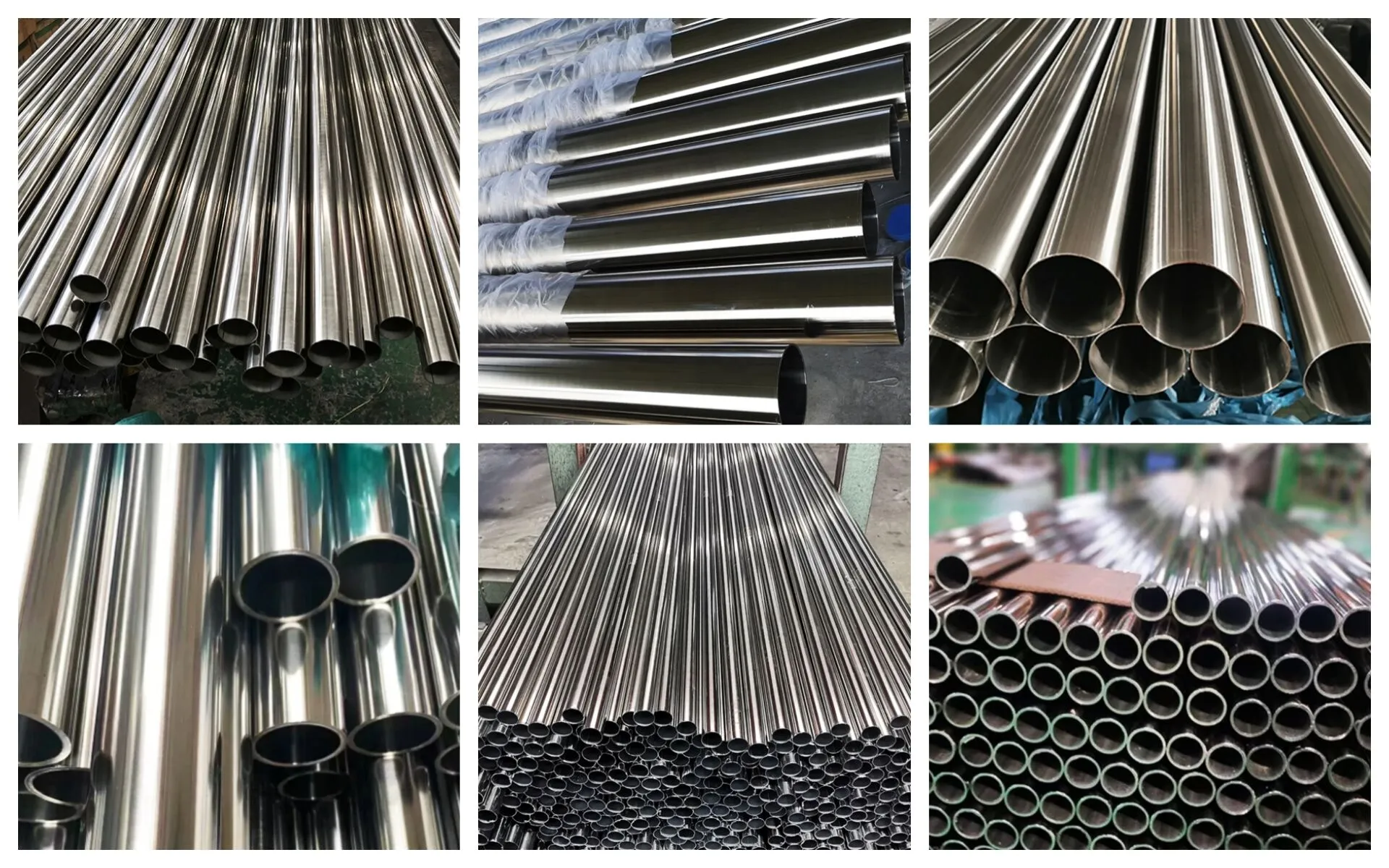

| Surface Treatment | Polishing, annealing, pickling, bright finish |

| Production Process | Cold rolling / Hot rolling |

| Steel Grades | 201, 202, 304, 304L, 304N, 309S, 310S, 316, 316L, 316N, 316Ti, 317, 317L, 321, 347, 347H |

| Execution Standards | ASTM A213, A312, A269, A778, A789; DIN 17456, 17457, 17459; JIS G3459, G3463; GOST 9941; EN 10216; BS 3605; GB 13296 |

| Tolerance | – Outer diameter: ±0.5mm – Thickness: ±0.05mm – Length: ±5mm |

| Testing Items | Flattening test, expansion test, hydrostatic pressure test, intergranular corrosion test, heat treatment test |

| Packaging | Standard export packaging |

| Payment Methods | Telegraphic Transfer (T/T), Letter of Credit (L/C), Western Union |

| Delivery Time | 10 working days upon receipt of the deposit |

| Application Areas | Decoration, construction, upholstery, water supply systems, handrails, railings, staircases, doors, windows, balconies, fences, benches, furniture, etc. |

| Processing Services | Custom processing, slitting (Kaiping), cutting, pattern processing |

Physical properties and chemical properties:

Physical properties and chemical properties:

Physical properties

Density:

The density of stainless steel pipes varies slightly depending on the type of steel, generally between 7.75 and 8.05 g/cm3. For example, the density of 304 stainless steel is about 7.93 g/cm3, and the density of 316 stainless steel is about 7.98 g/cm3.

Melting point:

Usually around 1398-1454℃, and different alloy compositions will cause different melting points. For example, the melting point of 304 stainless steel is about 1400-1450℃, and 310S stainless steel has a relatively higher melting point of about 1470-1530℃ due to its high chromium and nickel content.

Coefficient of thermal expansion: As the temperature changes, stainless steel pipes will expand and contract. Generally speaking, its coefficient of thermal expansion is between (10-20)×10⁻⁶/℃. For example, the thermal expansion coefficient of 304 stainless steel at 20-100℃ is about 17.3×10⁻⁶/℃.

Thermal conductivity:

Stainless steel has poor thermal conductivity, and its thermal conductivity is generally between 10 – 30 W/(m·K). Taking 304 stainless steel as an example, its thermal conductivity is about 16.2 W/(m·K), which is much lower than metals such as copper (about 386 W/(m·K)) and aluminum (about 203 W/(m·K)).

Electrical conductivity:

The electrical conductivity of stainless steel pipes is also relatively weak, and its electrical conductivity is usually between (1.3 – 1.6)×10⁶ S/m. The electrical conductivity of 304 stainless steel is about 1.4×10⁶ S/m, which is poorer than pure metals.

Chemical properties

Corrosion resistance:

This is one of the most significant chemical properties of stainless steel pipes. Stainless steel contains alloy elements such as chromium and nickel, which react with oxygen in the air to form a dense oxide film on the surface (the main component is Cr₂O₃). This oxide film can prevent the internal metal from further chemically reacting with external substances, making it have good corrosion resistance. For example, 304 stainless steel has good corrosion resistance in the atmosphere, water and some weak acid and alkali solutions; 316 stainless steel has better resistance to chloride ion corrosion due to the addition of molybdenum, and is often used in marine environments or in contact with chloride ion media.

Antioxidation:

At high temperatures, stainless steel pipes can still maintain good antioxidation properties. The presence of chromium enables stainless steel to form a stable oxide film at high temperatures, preventing further oxidation. Stainless steels such as 309S and 310S have high chromium and nickel content, can be used for a long time in high temperature environments, have good antioxidation properties, and can be used for high-temperature furnace tubes, heating elements, etc.

Chemical stability:

Stainless steel pipes are relatively stable in general chemical environments and are not easy to react violently with common chemicals. However, under certain conditions, such as strong oxidizing acids (such as concentrated nitric acid and sulfuric acid), high temperature and high concentration alkali solutions, stainless steel may also corrode or react chemically. However, by adjusting the composition and surface treatment process of stainless steel, its stability in specific chemical environments can be improved.

Application:

Stainless steel pipes are widely used in many fields due to their excellent corrosion resistance, strength and aesthetics. In architectural decoration, they are often used for handrails, railings, door and window frames and curtain wall decorations. They are not only durable, but also can enhance the appearance of the building. The food and pharmaceutical industries use their hygienic, non-toxic and easy-to-clean characteristics to make food processing equipment, pharmaceutical pipelines and storage containers to ensure that the production process is safe and pollution-free. In terms of kitchen and bathroom supplies, stainless steel water pipes and faucets are the first choice for household water facilities because of their corrosion resistance and long service life. In the industrial field, special types of stainless steel pipes such as 316 are used in chemical pipelines and oil extraction equipment, which can withstand strong acids, strong alkalis and high temperature and high pressure environments. In transportation, stainless steel pipes are used to manufacture automobile exhaust systems and subway car frames to achieve a balance between light weight and high strength.