PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

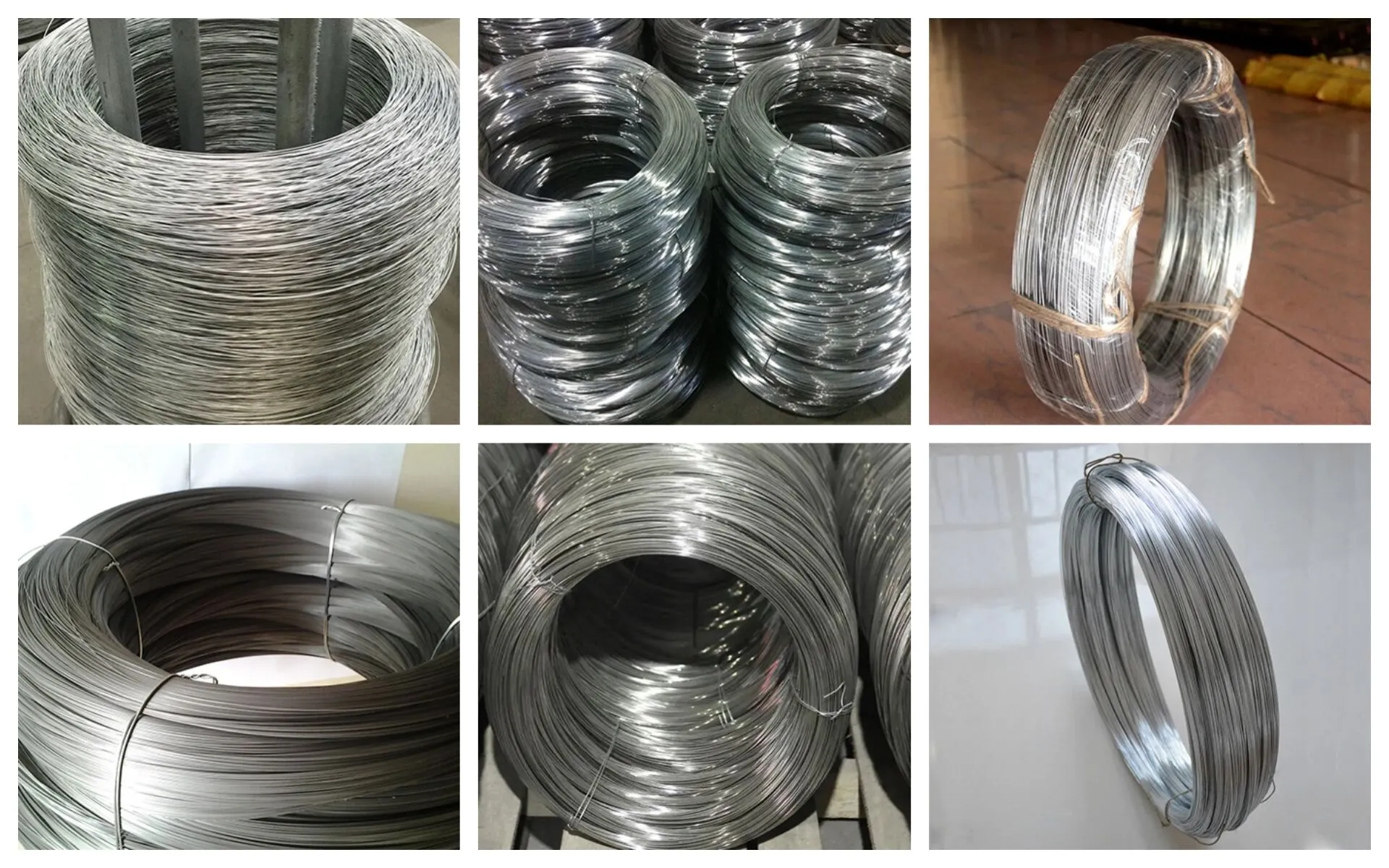

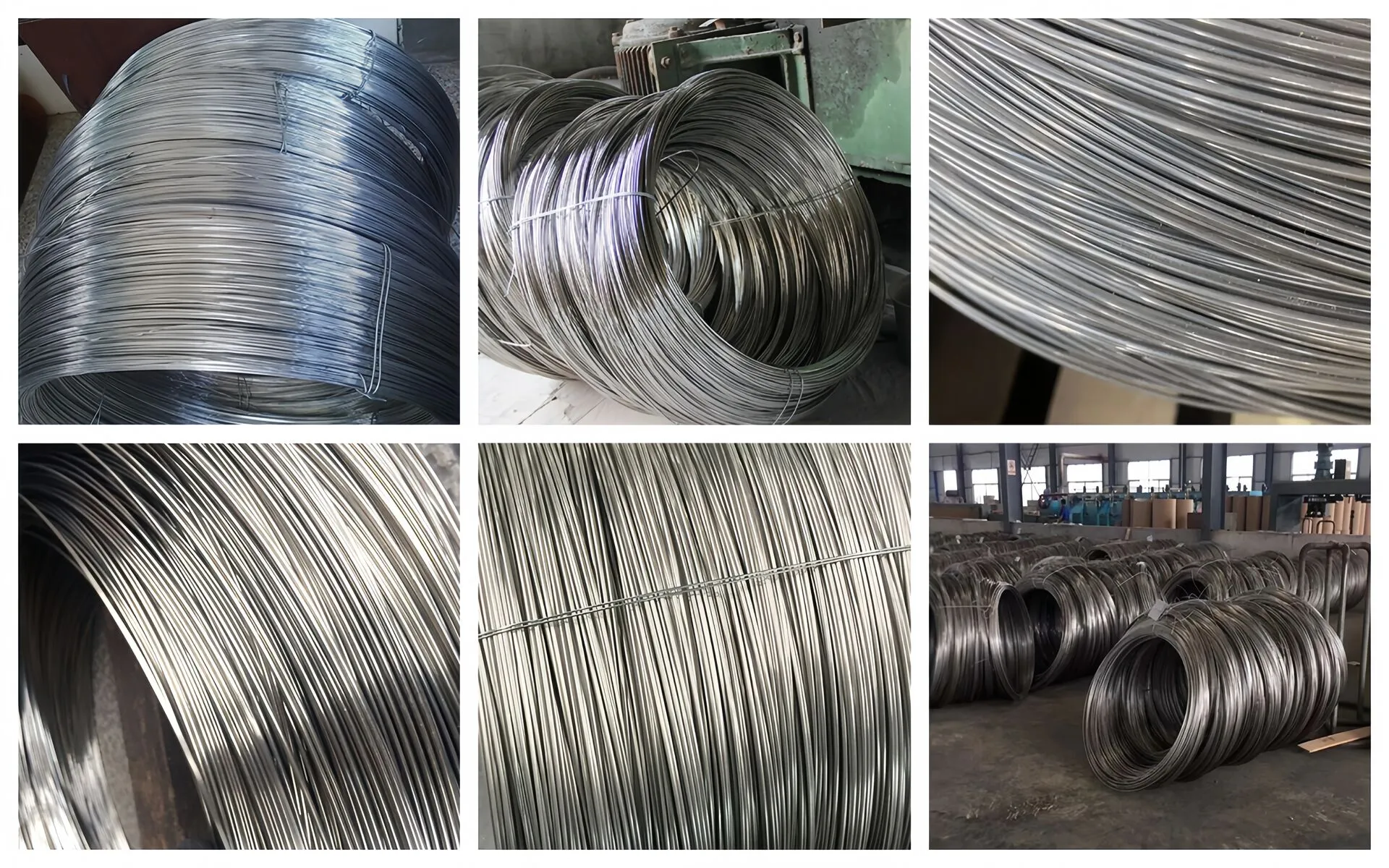

Stainless steel wire

![]() Whatsapp : +8613176258356

Whatsapp : +8613176258356

![]() Email : [email protected]

Email : [email protected]

Product details table:

| Item | Details |

|---|---|

| Product Name | Stainless steel wire |

| Material Type | Common: 304 (18Cr – 8Ni), 316 (16Cr – 10Ni – 2Mo), 430 (16 – 18Cr). Cr, Ni, Mo enhance corrosion resistance. |

| Execution Standard | GB/T 4240, ASTM A580, EN 10088 – 3, JIS G4313 |

| Specifications | Diameter: 0.02 – 12mm; Tensile strength: Soft (≤750MPa), Light drawn (750 – 1050MPa), Full hard (≥1450MPa); Surfaces: Bright, Matt, Polished, Coated; Packaging: Spool, Coil, Bulk |

| Mechanical Properties | Elongation: Soft ≥25%, Full hard ≥5%; Elastic modulus: 193 – 207GPa; Density: 7.93g/cm³ (304), 7.98g/cm³ (316) |

| Physical Characteristics | Non – magnetic (304/316 normal), Weakly magnetic (430/cold worked); -200℃ – 800℃; Thermal expansion: 16 – 18×10⁻⁶/℃; Thermal conductivity: 15 – 17W/(m·K); Conductivity: 1.4×10⁶ S/m |

| Corrosion Resistance | Resists atmosphere and fresh water; 316 is seawater – resistant; Caution in strong acids/bases or high chloride environments |

| Typical Applications | Industrial: Springs, Meshes; Home: Safety nets; Medical: Sutures; Food: Baskets; Electronics: Shielding meshes |

| Processing Performance | Bendable, weldable; Surface treatments for extra protection |

| Packaging Method | Moisture – proof paper, plastic film, protective sleeves; Spool/coil on pallets/wooden cases |

| Delivery Period | Regular: 3 – 7 days; Custom: 7 – 15 days |

| Quality Certifications | ISO 9001, SGS, RoHS; Optional salt spray and intergranular corrosion reports |

Physical properties and chemical properties:

Physical properties and chemical properties:

Physical properties

Appearance:

Usually presents a silver-gray metallic luster, smooth surface, and high reflectivity.

Density: Varies depending on the material, such as 304 stainless steel density is about 7.93g/cm³, 316 stainless steel density is about 7.98g/cm³.

Magnetism:

304 and 316 stainless steel are usually non-magnetic under normal conditions, but may produce certain weak magnetism after cold processing; 430 stainless steel generally has weak magnetism.

Thermal properties:

It has good heat resistance and can be used in the temperature range of -200℃ – 800℃. Its thermal expansion coefficient is about 16 – 18×10⁻⁶/℃ (20 – 100℃), and its thermal conductivity is 15 – 17W/(m・K).

Electrical properties:

The electrical conductivity of stainless steel wire is relatively low, about 1.4×10⁶ S/m.

Chemical properties

Corrosion resistance:

The main alloying element chromium (Cr) of stainless steel wire forms a dense chromium oxide passivation film on its surface. This passivation film can prevent oxygen, water and other corrosive substances from contacting the metal matrix, making it have good resistance to corrosion in the atmosphere, fresh water and general corrosive media. 316 stainless steel containing molybdenum (Mo) has stronger corrosion resistance to seawater and media containing chloride ions.

Oxidation resistance:

At room temperature and high temperature, stainless steel wire has good oxidation resistance, can resist the oxidation of oxygen in the air, and is not easy to rust and corrode. However, in an environment with high temperature, high humidity or the presence of specific corrosive gases, its oxidation resistance may be affected to a certain extent.

Chemical stability:

In a general chemical environment, stainless steel wire has high chemical stability and is not easy to react chemically with common chemicals such as acids, alkalis, and salts. However, corrosion may occur in a strong oxidizing acid (such as concentrated sulfuric acid, concentrated nitric acid) or a high concentration of chloride ions.

Application:

Stainless steel wire is widely used in multiple fields due to its characteristics such as high strength, corrosion resistance, and easy processing. In industrial manufacturing, it is used to make springs, screen meshes, wire ropes, and fasteners to meet the strength and durability requirements of mechanical structures. In home decoration, it is often used as protective nets, clotheslines, and decorative woven materials, combining practicality and aesthetics. In the medical field, because it is non-toxic and corrosion-resistant, it can be used to manufacture sutures, surgical instruments, and implant stents. In the food industry, baskets, conveyor belts, and processing utensils made of stainless steel wire meet hygiene standards and ensure food safety. In addition, in the field of electronics and electrical appliances, stainless steel wire is also used to make components such as shielding nets and cable armoring to play the role of electromagnetic shielding and mechanical protection.